Increased efficiency in electronics manufacturing through interdisciplinary collaboration

In electronics manufacturing, the continuous optimization of production processes is of central importance. As part of a project on data-driven process improvement, researchers investigated how throughput time in an SMT line could be reduced without compromising product quality.

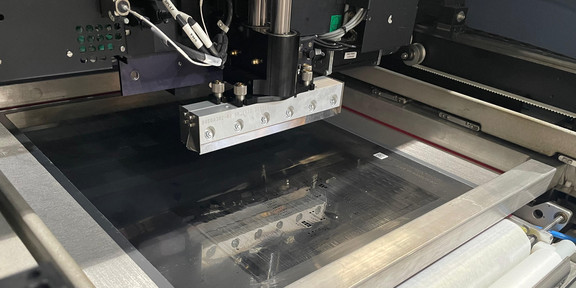

The focus was on the solder paste printer, which is responsible for over 60% of all quality deviations. An interdisciplinary team of subject matter experts, IT specialists, and data scientists jointly analyzed the relevant process parameters, including squeegee speed and pressure. With the help of structured data analyses and experimental test series, correlations between process time and print quality were identified.

The role of the so-called citizen data scientist, who acted as an interface between production and data analysis, was particularly important. Targeted visualizations and joint workshops made complex data relationships tangible for the specialist departments and enabled data-based decisions to be made.

As a result, the process time for solder paste printing was reduced by a high single-digit number of seconds, significantly increasing the overall productivity of the SMT line. At the same time, print quality remained within the required tolerances.

The project exemplifies how data-driven approaches—combined with a deep understanding of processes and clear communication—can lead to sustainable improvements in electronics manufacturing.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/3/3/csm_Maschinenbau-I_06d0e1956d.jpg)