LBR-Zelle

Due to the increasing number of variants and the shortage of skilled workers, the industry's interest in human-robot collaboration (HRC) is growing steadily. This is accompanied by a growing need for engineers and production workers who both understand how such systems work and are able to operate them. One system that aims to qualify the user with regard to these requirements is the IPS lightweight robot demonstrator, which was developed as part of the CSC research project.

Hardware and Structure

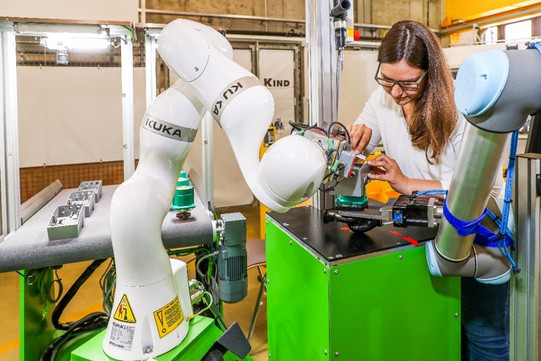

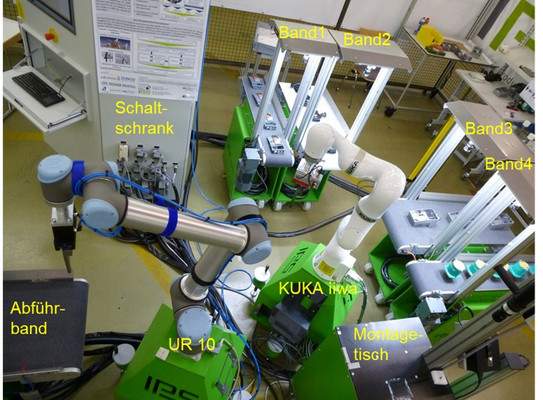

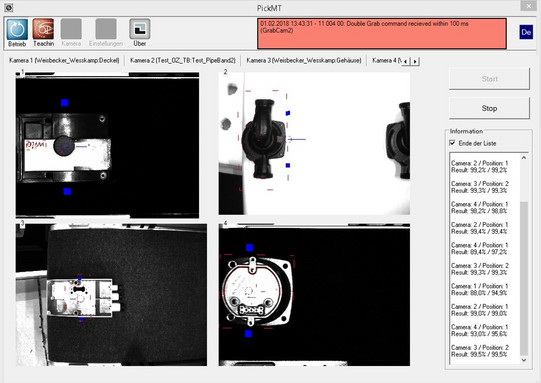

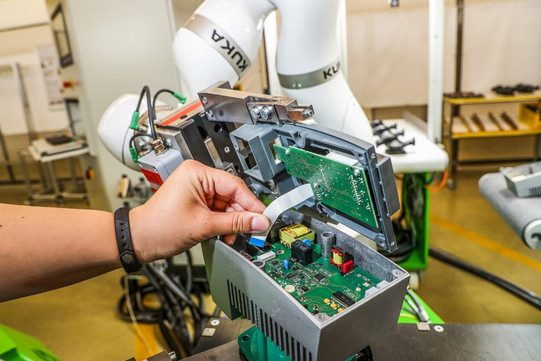

At the core of the LBR demonstrator are the lightweight robots KUKA iiwa 7 and UR10, which can collaborate with humans without a separating protective device, thus combining the repeatability of robots with the flexibility of humans. While the UR10 assumes the function of a flexible workpiece carrier in the developed application scenario, the KUKA iiwa 7 acts as a collaborative assembler. The material is supplied via four conveyor belts at whose delivery point a vision system detects the position of the components on the conveyor belts and communicates this to the KUKA iiwa 7. Special workpiece carriers are therefore not required. The assembled product is transported away via the UR10, which places the finished product on a designated discharge conveyor. In addition to the lightweight robots, the LBR demonstrator has an IoT architecture developed at the IPS that automatically updates the technical plant documentation after modifications.

Application Scenarios in Research and Teaching

In addition to research and training, the LBR cell is also used to demonstrate the possible applications of MRC systems using a real production process for companies. The research fields here range from actual human-robot collaboration to adaptive assembly and the digital twin. The research in the area of the digital twin includes the current documentation of the plant, which is essential for a transformable MRK plant, as every change requires a new risk assessment. In the process, the individual modules of the plant are digitally mapped in the software and linked to the real components. In this way, it is possible to reflect changes in the real plant in real time in the virtual image. The process data required for this was collected by retrofitting the plant with sensors.