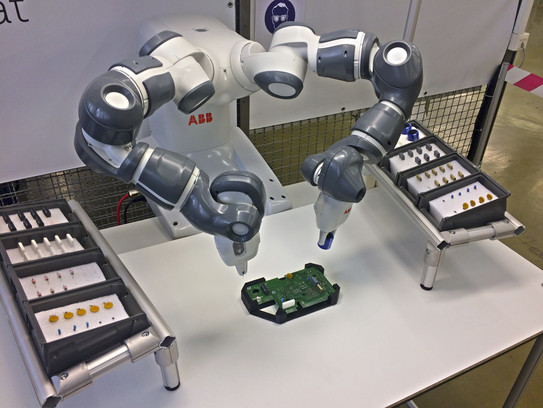

ABB YuMi

The ABB YuMi is a two-armed robot system whose structure and stature were modelled on a human torso. The YuMi's strengths are particularly evident when compared to conventional, single-arm robot systems, as YuMi can perform tasks both in parallel and more efficiently in terms of time due to its two "arms" and grippers working in parallel. To avoid potential collisions, the robotic arms have an integrated robot controller, via which the robot stops immediately in the event of collisions with humans. Due to the YuMi's efficient mode of operation in combination with the extensive safety features, YuMi holds great potential for direct cooperation with humans and consequently offers promising possibilities for use in industrial applications.

Technical Specification

- 0.5 kg Load capacity per arm

- 559 mm Reach

- 0.02 mm Accuracy

- 38 kg Total weight

- Protection class IP 30

Each arm of the YuMi has a total of seven flexibly movable axes and a modern two-finger gripper. In addition, the arms are equipped with a vacuum gripper and a high-resolution camera system for part recognition, which enables the robot to grip parts accurately. Depending on the application, own two-finger grippers can also be mounted, which are optimised for the respective application and can be produced e.g. by 3D printing.

Security

Potential collisions of the robot arms are prevented by an integrated robot controller. In addition, YuMi has a force detection system that detects and stops collisions with humans and objects in the environment.

Programming

The YuMi is programmed online via the local control panel. In addition, the RobotStudio software can be used for both online and offline programming on the PC. For this purpose, the software has a virtual image of the YuMi for simulation-supported programming and monitoring of the controller and the robot's status remotely. There is also an app for programming, but its scope and possibilities are severely limited.

Application Scenarios in Research and Teaching

On the research side, the focus is on the future-oriented design of cooperation between humans and robots. One concrete research question, for example, is how robot systems in production can be trained quickly and efficiently through human demonstration alone and without extensive prior knowledge on the part of the employee.

YuMi also offers ideal teaching opportunities to investigate the potential of a flexible lightweight robot and possible application scenarios in production. To this end, the students are investigating various questions around the topic of "Using the YuMi in production" and are developing a variety of concepts to constantly expand the YuMi's area of application.

With the help of the research results developed at the IPS, the potentials of industrial service robotics should become more transparent, especially for the area of assembly, and contribute to increasing the degree of industrial implementation of these innovative solutions.

Further planned application scenarios

One planned application scenario is the investigation of 'learning by demonstration'. The focus here is on typical pick-and-place movements for small parts assembly, as well as simple tool guidance movements (e.g. gluing, painting, rinsing), which are to be recorded by motion capture methods and transferred to the robot.