One year of INNO-SCREW: Milestones and progress at the innovation center for intelligent screwdriving technology

Completion of the first two work packages

After a year of intensive research, the project team successfully completed the first and second work packages. As part of the first work package, comprehensive requirements and success criteria for the innovation center were defined through several expert interviews. Discussions with experts from science and industry provided valuable insights into practical needs and formed the basis for further project work.

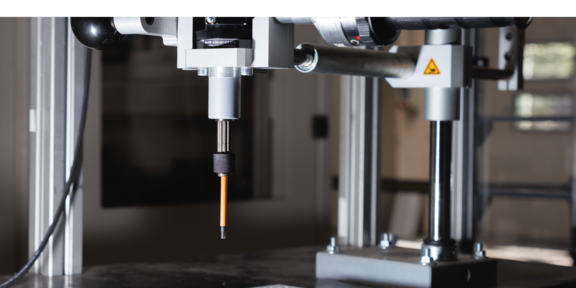

The second work package focused on the digital empowerment of the technical infrastructure. The four existing screwdriving stations—an automatic screwdriving station, a double-spindle screwdriving station, a hand-held screwdriving station, and a robot-based screwdriving station—were prepared for use in the research project. In addition, four further battery-powered manual screwdrivers were procured, which perfectly complement the screwdriving center. The final steps of the data connection are currently underway to enable continuous recording and storage of screwdriving process data.

Network development and expansion of expertise

Cooperation between industry and science is particularly important in screwdriving technology. That is why we are seeking active exchange with existing networks and other companies. Participation in the VDA Assembly Control Working Group provided important inputs, enabling valuable contacts with bolting experts from industry as well as in-depth specialist knowledge in the field of quality assurance. In addition, visits to the SchraubTec trade fairs in Landshut and Bochum offered excellent opportunities for direct exchange with manufacturers and users. Participation in specialist presentations and personal contact with leading companies in screw technology, both through the VDA working group and through visits to trade fairs, contributed equally to networking and competence building. These activities provided important impulses for further project work and enabled the innovation center to be even more closely aligned with practical needs.

Outlook: Data collection and experimental studies

With the completion of the data connection, the project is now entering a key phase: In the coming months, systematic data collection will begin with faulty and normal screw connections. Various fault patterns will be deliberately induced and documented in order to create realistic data sets for anomaly detection and fault classification using machine learning methods. This data will not only be used for our own research, but will also be made available in the spirit of “open science.”

The project team is convinced that INNO-SCREW will make an important contribution to the digitalization of quality management in industrial manufacturing. The innovation center is to be established in the long term as a platform for research, knowledge transfer, and cooperation between science and industry.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/3/3/csm_Maschinenbau-I_06d0e1956d.jpg)