Finalization of the VDMA standard sheet on reference planning processes is gaining momentum

The objective of the research project SUPPLy is to develop a automation-friendly charging station outlet module through simultaneous product and process development, with a special emphasis on flexible and scalable automation concepts.

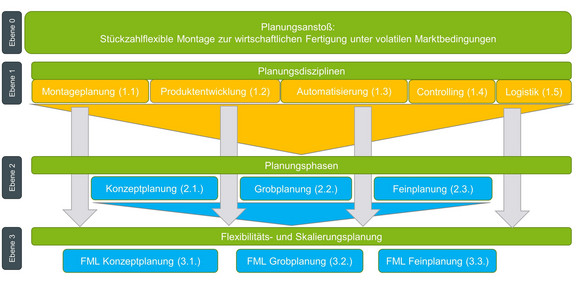

In close collaboration with FAPS (Institute of Factory Automation and Production Systems at the Friedrich-Alexander-University of Erlangen-Nuremberg) and Compleo Charging Solutions AG, a reference planning process has been developed, with a particular focus on product and process planning of stepwise scalable assembly concepts. The developed planning process is well-structured and divided into a specific number of planning steps to ensure a continuous, process-oriented approach. The planning process particularly focuses on the following five aspects: assembly system planning, human-robot collaboration, scalability, variable degree of automation, and cost-effectiveness. The overall concept of the planning methodology enables simultaneous development between product and process development.

The proposed reference planning methodology has been submitted to the VDMA (German Engineering Federation) as a proposal for the creation of a standard sheet and is currently being discussed by member companies in technical working groups. After the joint review, the results will be documented and published as a new "state of the art" in a VDMA standard sheet.

Further research in the SUPPLy project will focus on volume-dependent automation concepts for the assembly of the developed outlet module. Practical studies on robot assembly will take place in the laboratory areas of IPS and FAPS.

For more information, please visit the project website for „SUPPLy“.