IGF research project AutoTHT gets underway

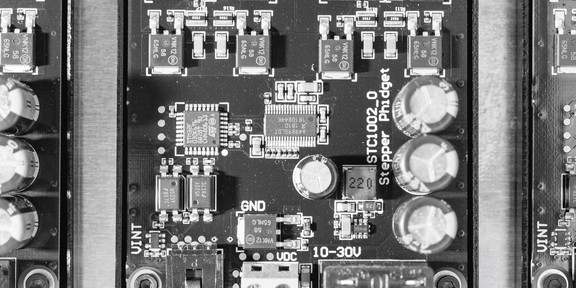

The objective of the project is to develop a strategic guideline for the implementation of robotic through-hole assembly. To this end, existing as well as innovative technologies for the automation of THT assembly (Through-Hole Technology) are systematically analyzed and, where appropriate, experimentally validated. In parallel, a universal methodology for the description of THT production systems is being developed. This methodology is intended to enable users to independently integrate future technological developments into existing comparative evaluations. The guideline is primarily aimed at small and medium-sized EMS providers (Electronic Manufacturing Services), supporting them in the integration of robotics while taking economic and ergonomic criteria into account.

The initial meeting marked the official project kick-off between the research team of RIF e.V. and the involved industrial partners. The project advisory board (PA), composed of representatives from the industry, assumes a key role: it accompanies the scientific work and provides practice-oriented impulses.

During the meeting, the project objectives and timeline were presented. A major focus of the subsequent discussion was on the specific challenges of through-hole assembly, including deformed component leads, the required flexibility in component feeding, high product variability, and significant economic pressure. The PA members contributed their specific experiences and requirements, highlighting the relevance of a universal and modular solution.

This kick-off laid the foundation for constructive collaboration. The discussions confirmed the shared vision of maintaining the long-term competitiveness of EMS providers in Germany through automated THT processes and sustainably increasing production efficiency.

We would like to thank our project partners for the successful kick-off and look forward to continued synergistic collaboration.