Upcoming final project meeting of the research project PrEPFlow

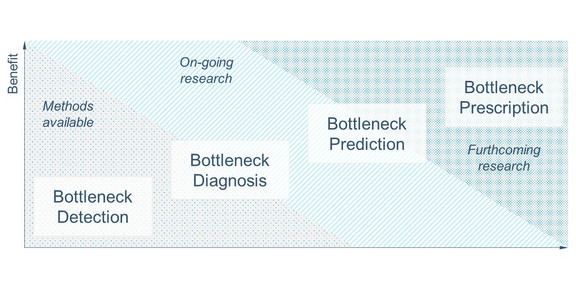

Over the past two years, the research project "Prediction of dynamic bottlenecks in directed material flow systems using machine learning methods (PrEPFlow)" has focused on the adaptation of successful machine learning methods for real-time capable bottleneck prediction in aligned material flow systems. This should enable manufacturing companies to predict weaknesses in the material flow at an early stage so that they can initiate preventive measures against upcoming bottleneck issues (e.g. output losses). Currently, the research results on predicting dynamic bottlenecks are on their way to be published in a renowned journal. However, the project team would like to present the prediction results to the PA of PrEPFlow in a practical way at an early stage. For this purpose, interested and PA-companies are invited to be a part of the final PA-meeting on June 20. If you are interested, please contact Jörn Schwenken (+49 231 755 5187).

During the full-day event, the focus will be on the implementation of results in socket assembly by Albrecht JUNG GmbH & Co. KG. At the pilot user, a part of the results was integrated into the Dynamic Value Stream Analysis (DVSA), so that an application directly on the production system is possible. In addition to the bottleneck prediction, an interview study on bottlenecks and preventive measures against predicted bottlenecks was conducted with the PA-companies in the past months. The results are summarized in a catalog of measures, which will be presented to the PA-companies in the final meeting. In addition, an IT tool for bottleneck management was developed. This will also be presented and made available to the public after completion of the project.

The project team of the Institute for Research and Transfer RIF e.V. is looking forward to your participation.