DAPRO

Data-driven Process Optimisation with the Help of Machine Learning in the Beverage Industry

(Project duration January 2019 to December 2021; project processing is carried out by RIF e.V., Production Systems Department)

Problem

Increased price and competitive pressure as well as initiatives to increase energy and resource efficiency pose major rationalisation challenges for the beverage industry. Existing approaches to process optimisation are reaching their limits in biochemical processes with complex combinations of different influencing variables. Solution approaches from the field of machine learning do not yet exist in the beverage industry. Both machine and plant manufacturers as well as operators have recognised the added value of the generated data for increasing efficiency up to its use as an independent economic good and are working together on solution patterns for data-driven process optimisation with the help of machine learning.

Objective

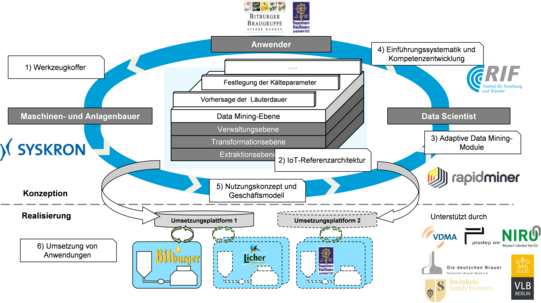

The aim of the DaPro research project is to develop a modular reference architecture for collaborative data use in the beverage industry to enable data-driven process optimisations. The close cooperation between users, machine and plant manufacturers enables the development of innovative, data-driven process optimisations and promotes the digitalisation efforts of the process industry. The focus is on the development of a toolbox of data mining modules and an IoT reference architecture for the beverage industry. In parallel, exemplary use cases are defined and implemented at the application partners. These practical examples enable the construction of specific analysis modules and the validation of created solution patterns.

Procedure and Division of Labour

The joint project is designed to run for three years. At the beginning, the basics for the development of the reference architecture must be worked out. For this purpose, the current state of the beverage industry will be recorded and the requirements for the reference architecture defined. Subsequently, the reference architecture will be conceptualised and designed. This includes the creation of various data mining modules within the framework of a toolbox, the consideration of various benefit concepts and the development of corresponding competences. At the same time, the design of practical application scenarios and their subsequent implementation take place. The results obtained in the context of the application serve both to further develop the overall system and to validate it. These results are transferred to science and practice.

Research, Development and Application Partners

Funding Reference

This research and development project is/was funded by the Federal Ministry for Economic Affairs and Energy in the programme "Strategic Individual Projects - Data as an Economic Asset" (funding code 01MT19004D) and supervised by the German Aerospace Center (DLR) project management organisation.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)