Holistic Production Systems for Logistics Service Providers

Holistic Production Systems for Logistics Service Providers

Development of a Management Toolkit for Logistics Service Providers to Optimise Performance Based on the Principles of Holistic Production Systems

Problem

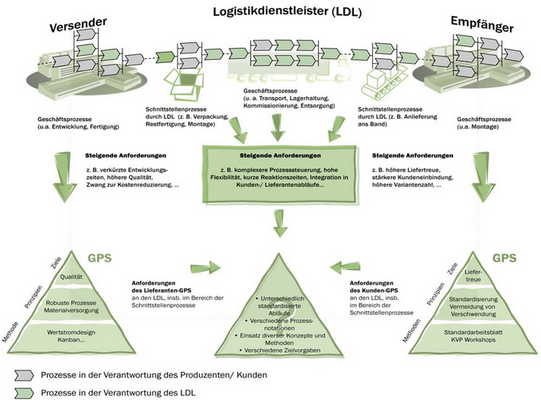

As providers of core logistics services between producer and customer, logistics service providers (LSP) are an important element of the supply chain. Due to the increasing efforts of industry to concentrate on its own core competencies, LSP are given the opportunity to take over the entire internal logistics of the customer and other tasks (e.g. simple assembly activities) in addition to the classic inter-company logistics services. This expanded range of tasks requires extensive organisational methodological competence.

In manufacturing companies, this is often ensured through the use of Holistic Production Systems (HPS). HPS are to be understood as hierarchical frameworks for the classification and categorisation of organisational principles and methods and have their origin in the Toyota Production System. Starting from the automotive industry, HPS are spreading in numerous value chains and industries. Of particular importance is that no transfer of this concept to LSP has taken place so far, although almost half of these principles and methods can be assigned to the field of logistics.

Objective

In view of the increase in the range of services offered by logistics service providers and the spread of HPS in manufacturing companies in numerous sectors and stages of the value chain, the primary objective of the research project is to intensively penetrate the effects of these developments in order to develop an adapted HPS reference model for logistics companies. With this model, the basics, principles and methods of HPS will be transferred into an adapted management toolkit for logistics service providers, supplemented in a targeted manner and made usable for them, so that LSP can acquire the HPS methodological competence that will be required in competition in the future. To this end, the following central research questions are to be answered:

- Which of the HPS building blocks used in production companies are relevant for logistics service providers, or which additional principles and methods used by logistics and service companies to organise service provision should be included in an adapted set of management tools?

- How are the interfaces between the production systems of the customers or suppliers and the counterpart on the side of the logistics service provider to be designed and how can the necessary flexibility be achieved for the latter's system in view of the different company-specific forms of design at customers and suppliers?

In addition to supporting classic, operative logistics processes, the management toolkit also deals in particular with the special features of the indirect area (including the planning and control of complex logistics services, integration into the customer's processes) and the production-like or production-related areas at logistics service providers. For this purpose, the specific conditions of use and requirements for targeted methodological support of the processes concerned must be determined and the achievable benefits for the service provider and its clients must be worked out. In the context of the company-specific configuration and adaptation of the reference model, the integration of additional principles and methods should also be systematically supported. Finally, building on the existing experiences of other sectors and companies, the research units will derive guidelines for the implementation of the management toolkit as well as critical success factors for the application of HPS by logistics service providers.

Procedure

In order to support logistics service providers in dealing with the HPS issue and in deriving and implementing internal organisational measures, a management toolkit is being developed to familiarise them with developments in the industrial sector and to support them in setting up, introducing and optimising concepts tailored to their specific requirements. In detail, the following approach is envisaged:

- A comprehensive HPS reference model will bundle and structure the principles and methods used in existing production systems in the industrial sector and in the logistics service provider environment that can be considered for inclusion in a HPS for LSP. The components to be included are not only to be aligned with the traditional, operative service provision processes (transport, handling, storage), but rather adequate methodological support for the entire service spectrum of the service providers is to be ensured (e.g. also planning of logistical services, scope of remaining production).

- The configuration of a company-specific HPS based on the generally valid reference model is supported by an evaluation system, which suggests suitable building blocks against the background of the entrepreneurial strategies and framework conditions of logistics companies and enables the expansion of the HPS construction kit with additional components.

- In order to assist logistics companies with the introduction and anchoring of a regulatory framework after it has been configured, a HPS implementation guide for LSP is being developed - based on known procedures in other sectors. In view of the specific features in the LSP environment, which arise, for example, due to the large number of cross-company interfaces through contact with producers and customers, this guideline will also be tailored to the needs of service providers by integrating, among other things, guidelines for HPS interface design and for the integration of the supply chain (coupling options to the producer or customer HPS).

- A system of key performance indicators for LSP, which is adapted to the logistical service provision processes, serves to control the implementation as well as to monitor the success and further optimisation of the HPS application in the service environment.

Following on from the "user catalogue", which is a result of an already completed project, the results of the planned project will be prepared accordingly and made accessible in a linked user catalogue.

In order to provide all interested companies with easy access to the project results, the user catalogue will be made available on the Internet (at www.modernisierungskonzepte.de).

Publications

- Deuse, J.; Keßler, S.; Wischniewski, S.: Ganzheitliche Produktionssysteme für Logistikdienstleister - eine Aufgabe für die nahe Zukunft. In: Jahrbuch Logistik 2006, S. 46-51.

- Droste, M.; Keßler, S.; Uygun, Y.: Ganzheitliche Produktionssysteme für Logistikdienstleister. In: Zeitschrift für Wirtschaftlichen Fabrikbetrieb, Bd. 103, Heft 9/2008, S. 594-597.

- Keßler, S.: Gestaltungsrahmen Ganzheitlicher Produktionssysteme bei Logistikdienstleistern.In: Jahrbuch Logistik 2009, S. 271-276.

- Kuhn, A.; Deuse, J.; Keßler, S.; Droste, M.: Developing an organisational framework based on lean production for logistics service providers. In: Logistics Research, 1 (2009) 2 (eingereicht).

- Kuhn, A.; Deuse, J.; Keßler, S.; Droste, M.: Endbericht: Ganzheitliche Produktionssysteme für Logistikdienstleister. Technische Universität Dortmund, Dortmund, Oktober 2009.

- Keßler, S.: Entwicklung eines Gestaltungsrahmens für Ganzheitliche Produktionssysteme bei Logistikdienstleistern. In: Kuhn, A. (Hrsg.): Reihe Fabrikorganisation, Dissertation, Verlag Praxiswissen, Dortmund, 2008.

- Keßler, S.: Lean Logistics Service Provider – Geschäftsmodell für den Logistikdienstleister der Zukunft? Beitrag auf logistics.de in der Rubrik Forschung und Entwicklung. Dortmund, 2009.

- Droste, M.; Keßler, S.: Prozesse von Logistikdienstleistern ganzheitlich planen und gestalten. Vortrag im Rahmen des ersten Industrieworkshops zum Forschungsprojekt. Technische Universität Dortmund am 05.09.2008.

- Droste, M.; Keßler, S.: zur Anwendung Ganzheitlicher Produktionssysteme bei Logistikdienstleistern. Vortrag im Rahmen des zweiten Industrieworkshops zum Forschungsprojekt. Technische Universität Dortmund am 29.05.2009.

- Keßler, S.: Gestaltungsrahmens für Ganzheitliche Produktionssysteme bei Logistikdienstleistern. Kolloquiumsvortrag an der Technischen Universität Dortmund am 31.07.2008.

- Keßler, S.: Ganzheitliche Produktionssysteme für Logistikdienstleister. Vortrag im Rahmen der Konferenz Logistik Management 2009, Hamburg, 02.-04.09.2009.

- Uygun, Y.: Studienergebnisse zu Lean Production-Ansätzen bei Logistikdienstleistern. Vortrag im Rahmen des zweiten Industrieworkshops zum Forschungsprojekt. Technische Universität Dortmund am 29.05.2009.

Funding Reference

The research project (research project no. 15104 N) has been funded from the budget of the Federal Ministry of Economics and Technology via the Federation of Industrial Research Associations "Otto von Guericke" e.V. on behalf of the Federal Logistics Association.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)