QU4LITY

QU4LITY - Digital Reality in Zero Defect Manufacturing (ZDM)

(Project duration: January 2019 to March 2022)

Problem

Due to increasing global competition, customer requirements and the demand for increasingly individual and personalised products and services are rising. At the same time, the globalisation of markets is leading to less acceptance of high product prices, so that companies are pushing for efficient and dynamically acting production and development. In this context, the EU project "QU4LITY" focuses on the realisation of an application-oriented and data-driven Zero Defect Manufacturing (ZDM). The focus is on the development of strategies to achieve competitive advantages for European industry. The main research focuses are the further development of predictive quality management, the development of methods for avoiding defect propagation and reducing energy consumption, as well as principles for reducing rejects.

Objective

The research focus of the IPS is the development of interoperable digital infrastructures for ZDM by exploring industrial applications of data analysis. An essential aspect of consideration is the reduction of error costs of automatic process control by reliably anticipating the resulting product quality already during the production process. On the basis of the anticipated product quality, action measures are to be derived for the subsequent production process, so that the test efficiency is increased in the entire value stream. The latter objective requires the development and integration of virtual sensors in the production processes to ensure detailed and at the same time digital documentation.

The integration of Big Data Analytics and AI (Artificial Intelligence) processes in the Amberg electronics plant of Siemens AG is being researched for the true-to-life depiction of this objective. A special focus is placed on the high number of variants and the low number of defective components that can be analysed, which are common in the production of electronic components.

Procedure

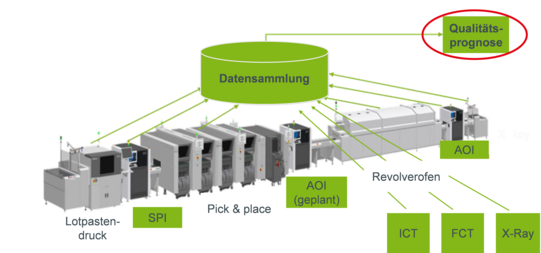

To achieve the described objective, four work steps are planned in the project. These will be successively researched and implemented in cooperation with the Amberg electronics plant of Siemens AG. The following figure illustrates the production line considered in this research project together with the measuring techniques it contains.

Funding Reference

The project "Digital Reality in Zero Defect Manufacturing" is funded by the European Commission (Horizon 2020).

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)