ReiMaFlu

Material Flow Systems Suitable for Cleanliness - Development of a Guide for the Design of Material Flows Suitable for Cleanliness along the Value Stream (ReiMaFlu)

(Project duration: April 2012 to March 2014)

Problemstellung

Die Reinheitsanforderungen an industriell gefertigte Bauteile haben in den letzten Jahren sehr stark zugenommen und werden auch in Zukunft weiter steigen. Unternehmen müssen heute nicht nur in der Lage sein, qualitativ hochwertige sondern auch saubere Teile zu produzieren.

Zurzeit wird die Bauteilsauberkeit häufig erst spät und zudem unsystematisch bei der Planung der Wertströme berücksichtigt. Um eine effiziente und reinheitsgerechte Planung zu ermöglichen sowie einmal erreichte Reinheitszustände zu erhalten und damit Verschwendung zu reduzieren, ist der Fokus von der reinen Betrachtung des Reinigungsprozesses auf den gesamten Wertstrom zu erweitern. Diese ganzheitliche Betrachtung führt zu einer Reduzierung des Reinigungsaufwands und somit zur Einsparung von Kosten, Energie u. Ressourcen.

Objective

The aim of the research project is to develop concepts for ensuring workpiece cleanliness in internal material flow operations (conveying, storage, order picking, etc.). Geared to the requirements of companies, a web-based selection guide for planners and logisticians is to be created, which supports the selection of material flow operations and corresponding packaging materials for specific cleanliness requirements in the entire value stream.

Standardised and structured selection methods in the form of a guide offer the possibility to quickly develop needs-based solutions and to build up a sustainable knowledge base for cleanliness-compliant material flow design. Furthermore, cleaning steps can be saved within the value stream if it is ensured that components are not re-contaminated by material flow operations.

Procedure

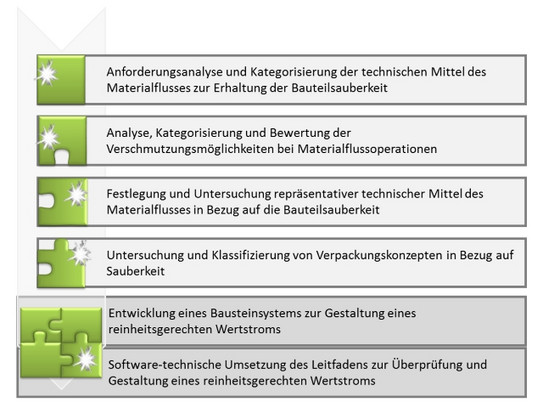

The starting point of the research activities is the identification and classification of the various technical means that are used in the context of internal logistics. Based on this categorisation, the requirements to be met by technical means in the material flow with regard to the maintenance of previously achieved states of cleanliness are identified. Several key questions are taken into consideration:

- What are the characteristics of the goods to be transported and what environmental conditions are they exposed to along the material flow?

- What are the requirements with regard to cleanliness?

- Which contaminations may occur and which must be prevented?

Based on the catalogue of requirements, the general procedure of the Failure Mode and Effects Analysis (FMEA) is adapted to pollution risks for the preventive analysis and qualitative evaluation of the different contamination possibilities within internal material flows. In particular, cleanliness-critical weak points and risks in the value stream are to be uncovered and possibilities for their avoidance identified.

Following the identification and categorisation of the requirements for internal material flows related to component cleanliness as well as the inherent contamination risks, the influence of the technical means for carrying out material flow operations on component cleanliness is evaluated by means of tests. This allows conclusions to be drawn about the expected back contamination. Each technical means influences the cleanliness status of the component in interaction with the component and in combination with other technical means.

After the essential interactions have been identified, different packaging concepts, as they are used in industry and product-specifically, can be quantitatively investigated with regard to component cleanliness in further tests. The cleanliness tests are carried out in the residual dirt analysis laboratory of the Institute for Production Systems.

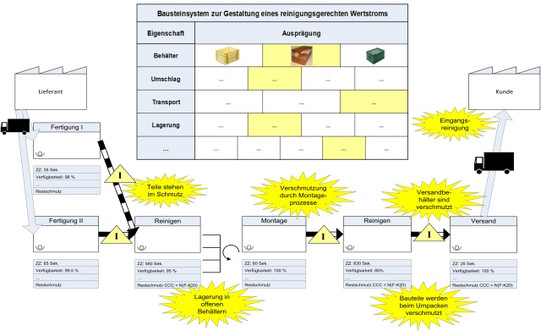

The results of the preceding investigations flow together in the development of a structured building block system for the design of cleanliness-compliant material flows. With the help of such a system, material flows of different types can be mapped, analysed or reconfigured in a practical way according to technical aspects and taking into account the possible risk of back contamination and the environmental influences that have an effect. Finally, the developed building block system will be implemented in the form of a practical guide.

In addition, an interactive internet-based software tool will be developed that will enable companies to independently map their material flow operations and to check and optimise them with regard to the maintenance of cleanliness conditions once they have been achieved.

Publications

- Zwinkau, R.; Krebs M.: Schlussbericht: Reinheitsgerechte Materialflusssysteme (ReiMaFlu), Herausgegeben von Jochen Deuse (Institut für Produktionssysteme, Professur für Arbeits- und Produktionssysteme), Technische Universität Dortmund. Dortmund, Juli 2014

- Krebs, Matthias; Zwinkau, Ronny (2014): Sauberkeitsplanung als Erfolgsfaktor bei der Auslegung von Wertströmen. In: 5. Fachtagung Technische Sauberkeit in Montage- und Produktionsprozessen. Stuttgart, Germany, 19.-20.05.2014

- Zwinkau, R.; Krebs, M: ReiMaFlu– Reinheitsgerechte Materialflusssysteme. Vortrag auf dem ersten Kolloquium (Sitzung des projektbegleitenden Aus- schusses) zum IGF-Forschungsvorhaben. Dortmund, 27.02.2013.

- Krebs, M.; Zwinkau, R.: Systemische Untersuchung von Einflussfaktoren der Technischen Sauberkeit (TecSa) auf den Wertstrom. Vortrag auf dem zweiten Kolloquium (Sitzung des projektbegleitenden Ausschusses) zum IGF-Forschungsvorhaben. Dortmund, 27.03.2014.

- Krebs, M.; Zwinkau, R.: Sauberkeitsplanung als Erfolgsfaktor bei der Auslegung von Wert- strömen. In: 5. Fachtagung Technische Sauberkeit in Montage- und Produktionsprozessen. Stuttgart, Germany, 19.-20.05.2014

- Krebs, M.; Zwinkau, R.: Medien und Energie bei der Teilereinigung effizient einsetzten, in: Nachhaltige Produktion, Interview, Jahrgang 3, Ausgabe 1, April 2013

- Zwinkau, R.; Krebs, M: Leitfaden zur reinheitsgerechten Gestaltung von Materialflüssen entlang des Wertstroms, Interview durch das Onlinemagazin Sauberkeit und Reinraum; 22.05.2014 URL: www.sauberkeit-und-reinraum.com/leitfaden-zur-reinheitsgerechten-gestaltung-von-materialfluessen-entlang-des-wertstroms/

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)