ROBOTOP

Modular, Open and Internet-based Platform for Robot Applications in Industry and Service (ROBOTOP)

(Project duration: June 2017 to May 2020)

Problem and Motivation

Industrial robot applications have to fulfil considerable technical requirements in order to guarantee high availability, quality and safety. In many cases, this results in highly complex applications. Until now, a correspondingly high level of expertise, a wealth of experience and extensive knowledge of the standardisation situation have been necessary for the successful planning of these robot systems. Especially for small and medium-sized enterprises (SMEs), this represents an entry barrier to the use of industrial (service) robotics applications. Based on the expected engineering effort as well as the high costs for the technical components and for the support services on the part of the system integrators, numerous robot solutions cannot be implemented at present or only to a very limited extent.

Powerful web platforms that map the complete engineering process from initial rough planning and component selection to support during integration and virtual commissioning are therefore a central key technology. These can ultimately pave the way towards a significant increase in the degree of implementation of innovative robot applications.

Objective

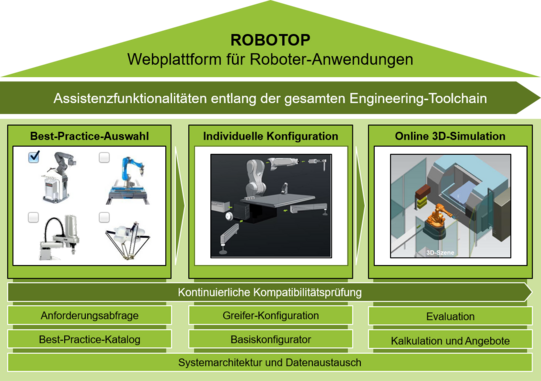

The aim of the ROBOTOP project is to develop a modular, open internet platform for industrial and service robots. This is to represent a foundation for opening up the mass market for robots in manufacturing, logistics and service applications. The platform optimises the planning processes on both the supplier and customer sides and thus links both groups directly with each other. The ROBOTOP platform offers extensive assistance functionalities in all phases of automation planning (see Fig. 1).

In the course of an initial best practice selection, potential end users first have the opportunity to describe their individual application scenarios (e.g. manual workplaces) using a structured and user-friendly questionnaire. Based on a continuously expanded compilation of industrially implemented best practices, suitable implementation examples are derived in an automated selection process. These serve as an initial concept proposal for the operational end user and also as a basis for the individual configuration process that follows on from this. In this process, suitable robot systems, peripheral components and gripping systems can be freely combined with each other, whereby the compatibility of the individual components is guaranteed at all times. To increase user-friendliness, the assembled systems can be transferred directly into a web-based 3D simulation. At the same time, users can make an initial assessment of the technical feasibility of the assembled solution for their specific application scenarios. Depending on this, it is then possible to go through the upstream process steps again to improve the planning results or, alternatively, to contact potential service providers directly for the purpose of an initial rough calculation and quotation.

Procedure and Division of Labour

The project consortium is interdisciplinary and consists of manufacturers of automation components and supporting software products, integrators and end users as well as university research institutions.

The IPS is coordinating the PlaNET sub-project with the focus on developing a best-practice selection. Initially, the IPS is developing a standardised questionnaire for identifying the automation-relevant properties of work systems, which will be used for the survey of users. By means of extensive research and practical surveys of industrial end users, a library of successfully implemented best practices will also be created. With the help of this formal database for robotics applications, a method for evaluating automation potential and recommending best practice solutions will then be designed. In the course of the holistic exchange, the IPS, in cooperation with the project partners from industry and research, will also develop requirements for the creation of the basic configurator and the associated compatibility test, and will accompany the final evaluation and optimisation of the overall system in the final project phase.

Research Institutions

Software Companies

Application Partner

Funding Reference

This project is funded by the Federal Ministry for Economic Affairs and Energy as part of the programme "PAiCE - Digital Technologies for the Economy" (funding code 01MA17009H) and is supervised by the German Aerospace Center (DLR).

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)