VariPro

Variability-based Machine Utilisation Planning for Customer Order-Specific Production in SMEs (VariPro)

(Project duration: September 2017 to August 2019)

Problem

In classic lean production, no distinction is usually made between value-added and non-value-added variability, although the former represents an important competitive factor, especially for companies in customer order-specific production. For example, a high product variety and the possibility of accelerated order processing are important, decisive competitive factors. However, the adaptation of lean production methods and techniques does not lead to the desired results. The reason for this is that the customer-induced variability in terms of product variety and delivery times as well as the associated erratic customer call-offs and strongly fluctuating stocks in circulation counteract efficient production control.

Due to this high variability and the increased flexibility requirements, a significantly greater production planning and especially control effort is necessary. Accordingly, machine scheduling as a core element of production planning and control must be designed in such a way that the value-adding variability prevailing in customer order-specific production is taken into account according to demand. Currently, there is no production control concept that adequately takes this problem into account.

Objective

The aim of the research project is to develop a variability-based MBP for SMEs in customer order-specific production, which is used in operational production planning. Through this methodology, users are able to profitably utilise value-adding variability so that a significant increase in efficiency in MBP and thus in production is achieved. For this purpose, variability criteria are derived, described analytically and transferred into a quantitative optimisation problem. This serves as the basis for an IT-supported MBP, which determines the optimal production sequence according to the order situation, taking into account individual framework conditions.

The research idea is based on the hypothesis that a differentiation into value-added and non-value-added variability represents a decisive competitive factor, especially for SMEs that produce according to customer orders. The derivation of variability criteria as well as the cascading and quantification of these is necessary in order to be able to make economic decisions on the basis of the prevailing variability so that the potential competitive advantage can be adequately realised.

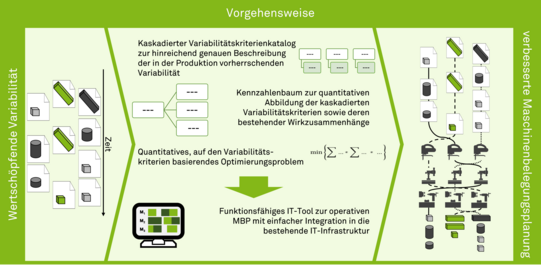

Procedure

The research project is divided into four work packages that build on each other (variability description and requirements definition for the MBP, conception of the variability-based MBP, validation, documentation and transfer of results). At the beginning, variability criteria are developed that are suitable for describing value-adding variability. These criteria are formulated in a cascaded manner and converted into a hierarchical form. Subsequently, those criteria are selected that have the greatest significance for production control. Suitable calculation methods are determined for this selection and calculable key figures are established. Any existing interdependencies between these key figures are determined and finally a key figure tree is obtained for the quantitative representation of the cascaded variability criteria. Based on this tree, requirements for the optimisation problem to be used can be derived. These requirements determine the possibility of adapting or extending already existing "(Flexible) Job Shop Scheduling" problems for the research project. In a next step, variability-related constraints and restrictions are formulated for the optimisation problem. Finally, the developed optimisation problem is transferred into an easy-to-use IT tool.

Funding Reference

The IGF project (19683 N / 1) of the Research Association Society for Transport Management and Logistics eV - GVB, Wiesenweg 2, 93352 Rohr was supported by the Federation of Industrial Research Association as part of the program for the promotion of industrial community research and development by the Federal Ministry for Economic Affairs and Technology funded based on a resolution of the German Parliament.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)