GreenIoT4KMU

Platform for the digital networking of SMEs in the electrical industry through the Internet of Things to conserve resources and reduce greenhouse gas emissions (Project processing ist carried out by RIF e.V., Production Systems Department)

Problem

The electrical industry in North Rhine-Westphalia faces the challenge of simultaneously digitising its production processes and making them more sustainable in the course of the twin transition. However, many small and medium-sized enterprises (SMEs) have a low level of digitalisation maturity, which means that sustainability potential remains untapped and the creation of reliable sustainability reports is very costly. In addition, there is a lack of effective exchange of sustainability information between companies, which makes holistic assessment and optimisation along the value chain considerably more difficult.

Objective

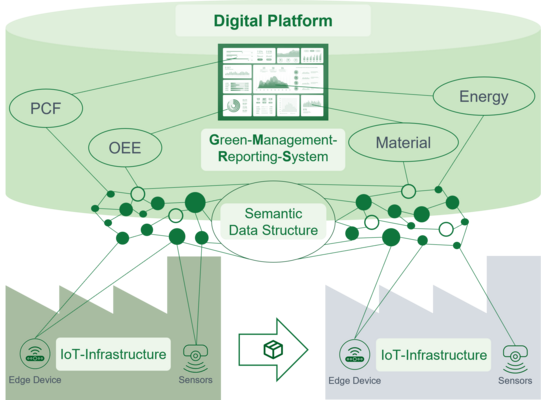

The project aims to develop a digital platform that collects, analyses and makes exchangeable sustainability data along the entire value chain of the electrical industry.

Based on this, a green management and reporting system will be created that integrates ecological and economic indicators and breaks down strategic and regulatory goals down to the operational shop floor level.

The platform will enable secure data exchange between companies through a data room-compatible IoT architecture and semantic description of data, thus laying the foundation for future cooperation in data ecosystems.

In the long term, this should reduce energy and resource consumption, lower CO₂ emissions and strengthen the competitiveness and innovative power of the electrical industry in North Rhine-Westphalia.

Approach

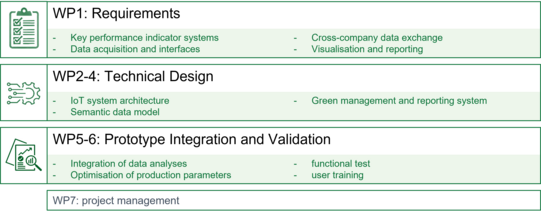

First, in work package 1, the system and user requirements are determined through interviews, process analyses and workshops in order to create a basis for technical development.

This is followed by the technical design in work packages 2 to 4: an IoT system architecture for data collection of sustainability parameters is developed, GreenKPIs are defined and a semantic data model is created that links product, process and resource data.

In the subsequent work packages 5 and 6, the system will be prototypically integrated, tested and validated. Application scenarios along the value chain for the production of a smart socket are available for this purpose.

Funding Reference

This project is funded by grants from the State of North Rhine-Westphalia from the ERDF/JTF programme NRW.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)