INNO-SCREW

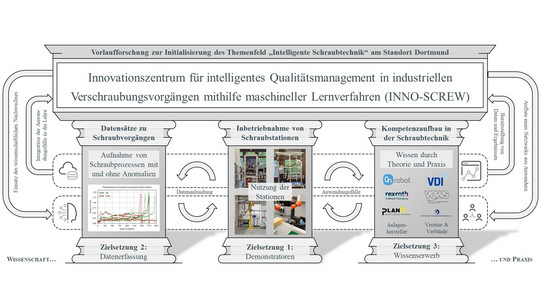

Innovation center for intelligent quality management in industrial screw driving processes using machine learning methods

Problem

Screwing is one of the most important joining processes in industrial production, but its quality assurance presents companies with major challenges. The statistical process control (SPC) methods currently in use reach their limits in complex applications. As a result, faulty screw connections are not fully detected and, in the worst case, end up in circulation. The consequences are costly disassembly operations, product recalls and potential damage to the company's image. This problem is intensified by the increasing individualization in production, which leads to a growing variety of possible defects. At the same time, there is a lack of publicly available data sets with real world datasets of industry, which would be essential for the development and validation of new quality assurance methods.

Objective

The project pursues a systematic approach to establishing an innovation center for intelligent quality management. The first target is the connection of 5 screwdriving stations as data suppliers. Four existing screwdriving stations will be technically upgraded and supplemented by a wireless station. These different stations - from an automatic to a robot-based to a manual screwdriving station - will be equipped with a consistent data acquisition infrastructure. The second objective is the experimental phase, in which both error-free and manipulated screwdriving processes are systematically carried out and documented. The data obtained will be processed and made available to the research community. This will be accompanied by preliminary work on anomaly detection using machine learning methods and the establishment of a network with regional industrial partners. The third objective of the project is carried out in parallel and describes the development of domain knowledge through targeted training measures.

Approach

The specific implementation will take place in five clearly structured work packages over a project duration of 30 months. Following the initial definition of requirements and success criteria, the technical infrastructure of the screwdriving demonstrators will be digitally enabled. This includes ensuring operational capability as well as implementing a consistent data connection and a monitoring concept. A particular focus is on the systematic execution of experiments, whereby normal screwdriving processes and manipulated error cases are recorded. The collected data will be validated by a preliminary experimental study and then made available to the research community. Accompanying measures such as training, network development and knowledge transfer ensure the sustainable establishment of the innovation center.

Funding Reference

The INNO-SCREW project is funded by EURONORM GmbH as part of the “INNO-KOM Innovation Competence” funding program of the Federal Ministry for Economic Affairs and Climate Action (BMWK).

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)