KoMPI

Performance-based, Digital Planning of Collaborative Assembly Systems and Integration in Variable Production Scenarios (KoMPI)

(Project duration: January 2017 - December 2019)

Problem

The assembly of industrial goods accounts for a very high share of value added in Germany's gross national product. In addition, Germany is one of the world's leading suppliers of equipment for assembly and handling technology. Due to increasingly volatile markets, individual and complex products as well as new process requirements - e.g. through Industry 4.0 - assembly is exposed to special transformation requirements. The development, design and introduction of innovative system solutions for the assembly of complex unit goods are therefore important. The focus here is on safe workplace design and cooperation between humans and robots in assembly. Furthermore, the adaptability of assembly systems is becoming increasingly important in order to be able to react to varying quantities and minimise investment risks. In the future, collaborative and adaptable assembly solutions will enable small and medium-sized enterprises in particular to benefit from cost and efficiency advantages and secure the innovation leadership of German assembly system manufacturers in the long term.

Planning a manual assembly workplace, in terms of work content and working time, is a complex task. Due to the variety of data to be taken into account, this is usually done today with specially developed software for modelling, simulation and optimisation of the work cycles of manual assembly processes. If a company today is considering the use of workplace systems in which humans and robots collaborate with each other, there are as yet no digital planning tools that can simulate and evaluate the use of the system in terms of automation capability, technical-economic suitability, ergonomics and safety. This is a strong barrier to the use of low-cost robots in assembly systems, not only for SMEs.

Objective and Approach

The aim of the planned research project is to develop a new method for the integrated planning and realisation of collaborative workplace systems in assembly with variable product scenarios. This should ensure that even companies with little experience and limited resources are enabled to successfully introduce collaborative work systems and to operate them economically in the long term, even with a strongly fluctuating variety of products and variants.

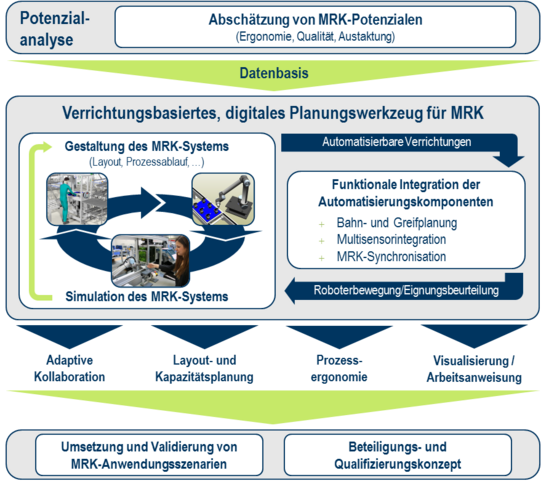

The results of the joint project support the entire MRI development process: The new method for the integrated planning and realisation of collaborative workplace systems in assembly is intended to support work planners in particular in the planning and design process. A selection system will first identify the workplaces with potential for human-robot collaboration, based on the analysis of existing manual assembly scenarios. The potential is limited in particular by the flexibility of the robots. The targeted linking of optical sensor technology and robots will expand the application areas of the robot systems. The digital design and evaluation of the collaborative workplace system is modelled with a generally valid planning method. The planning is carried out in accordance with the special assembly tasks in a direction-based manner and is supported by the robot and component libraries to be developed, whereby the technical integration of the robot and its components can be simulated. Subsequently, the implementation and integration are supported by a technical integration concept as well as an employee-oriented participation and qualification concept, so that existing technical and social barriers are reduced. Operational employees are also specifically integrated during ongoing operations via suitable human-machine interfaces to be developed, thus promoting acceptance for the use of HRC. Last but not least, this acceptance is also supported by the active participation of the social partners.

In summary, the equipment-based planning system in the form of a software solution for integrators and end users with user guidance appropriate to the requirements of MRI and the participation and qualification concept as a multimedia training guide for conducting seminars and workshops for users are available at the end of the KoMPI joint project. These two development results have been verified by means of the MRK applications planned, implemented and validated at and with the application partners in the project.

Division of Labour

The project is designed to run for three years and is divided into three phases:

In the first phase, the requirements for the planning and simulation system are recorded. Both technical restrictions and the cross-company and cross-sector requirements of the later users must be taken into account. In addition, the application scenarios for different product variants are defined. The application scenarios are chosen in such a way that they cover different branches of industry and the user companies also have medium-sized structures, so that transferability of the research results to the German corporate landscape is ensured. The analysis phase results in important aspects for the later training and education concepts for the employees in the collaborative assembly system as well as for the participation of the social partners. The first phase concludes with the architecture of the planning system to be developed and the specification of the software interfaces for linking the respective system components, such as the robot and periphery simulation with integrated component library, the tool for assessing the potential of MRC scenarios and the logic for the skill-oriented distribution of tasks to humans and robots.

In the second phase, the system will be developed and implemented and the training concepts will be worked out. An interface based on AutomationML and COLLADA will be used to connect the individual subsystems and thus to develop them simultaneously.

The final phase is the validation of the overall system. This is characterised by innovative application scenarios of collaborative assembly in the different sectors described above, which are planned and designed with the help of the developed system and finally implemented in real demonstrators at the users. The experiences from the digital planning and simulation of the user systems are used to optimise the planning system and to test the concepts of training and operational training.

Research- and Development Partner

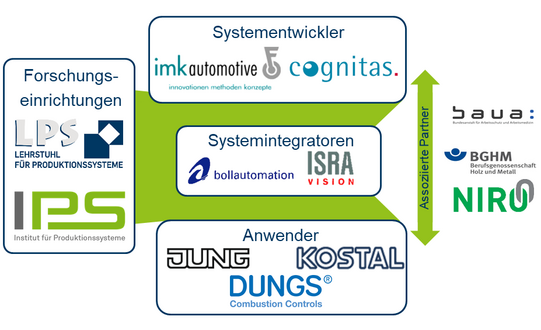

- TU Dortmund, Institute for Production Systems (IPS)

- Ruhr University Bochum, Chair of Production Systems (LPS)

- imk automotive GmbH

- ISRA Vision AG

- Boll Automation GmbH

- cognitas Society for Technical Documentation mbH

- Albrecht Jung GmbH & Co. KG

- Leopold KOSTAL GmbH & Co. KG

- Karl Dungs GmbH & Co. KG

Funding Reference

The project is funded by the Federal Ministry of Education and Research as part of the funding programme "Innovations for tomorrow's production, services and work" on the topic of "Assembly competence - collaborative and adaptable (KoMo)" and is supervised by the Karlsruhe project management organisation.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)