PrEPFlow

Prediction of dynamic bottlenecks in aligned material flow systems using Machine Learning

(Project duration January 2021 to June 2023; project processing is carried out by RIF e.V., Production Systems Department)

Problem

Fluctuating incoming orders, a broad product portfolio and complex, multi-stage production: these are all framework conditions that many manufacturing companies, especially in Germany, have been confronted with for more than just a few years. Static and easily manageable bottlenecks are thus a thing of the past in many production environments. Identifying and predicting dynamic bottlenecks is becoming a key competence in improving production efficiency and stability. Often, this is the key approach to further optimize system performance. Even though a large number of different approaches and methods exist in theory and research, their dissemination into practice often shows a clear need to catch up, especially in small and medium-sized enterprises. In industrial practice, problems in the application of theoretical approaches often only become apparent in very specific case studies. For a simplified start, users lack suitable methods and tools to identify for which companies and data situations individual procedures are best suited. In addition, there is a lack of practicable and efficient software support in the implementation based on the data available in the company.

Objective

The main objective of the research project is the development of a data-driven methodology for the prediction of dynamic bottlenecks in directed material flow systems using machine learning methods. Therefore, existing obstacles regarding data generation and processing in SMEs will be identified and reduced. Subsequently, the results will be transferred into an industry-neutral, user-friendly IT tool. As an accomplying step, measures for the target-oriented adaptation of production systems to avoid bottlenecks are to be developed with the support of the Project Advisory Committee (PA).

Approach

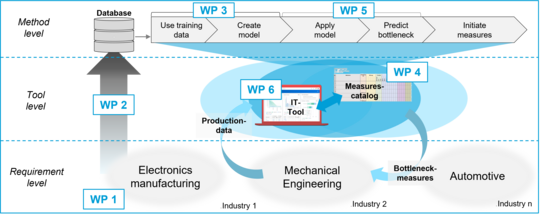

The research project is scheduled to run for 24 months and will be conducted in close cooperation with the members of the PA. Six work packages, which content rests upon the practice-oriented procedure model CRISP-DM (Chapman et al. 1999), divide the development of the project content. The work packages address different levels of consideration: The requirement level, the tool level and the method level. Starting from the requirements level, the researchers first collect user requirements and select a method for dynamic bottleneck identification. Based on this, they define data requirements at the tool level and gather production data. Represented by the analysis steps data preprocessing, modelling and evaluation of the CRISP-DM, the development and generalization of a method for the prognosis of dynamic bottlenecks takes place on the method level. In cooperation with the companies of the PA, the researchers will develop a catalog of measures, which addresses the handling of the predicted bottlenecks. Furthermore, the introduction and optimization of the bottleneck prediction in real aligned material flow systems represents a necessary step to test the prediction methodology in industrial practice. Finally, the researchers will transfer the methodology into a user-friendly IT tool, which uses production data from the application environment.

Research and development partners

PrEPFlow is a research project of the cooperation partner RIF e.V.. Companies from the electronics, automotive and automotive supplier industries as well as consulting companies and representatives of regional networks are participating in the PA.

Funding notice

The project PrEPFlow () of the German Logistics Association e.V. (BVL) - Schlachte 31, 28195 Bremen - is funded by the AiF within the scope of the program for the promotion of joint industrial research and development (IGF).

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)