VR in Industrial Engineering: New research cooperation between IPS and Audi started

- 2020

In order to perceive increasing digitization not as a threat to existing production and planning processes, but as an opportunity for the human-centered design of work, a strategic development of the IE is necessary. The goal is to increase planning quality and efficiency through virtual planning and safeguarding under the premise of designing human-centered, technological and organizational dimensions of work. The focus here is on planning workshops in which the planned processes are interactively tested for their feasibility on physical prototypes under the aspects of productivity, quality, ergonomics and resource usage. Due to the continuous development and improvement in the planning phase, the cost-intensive prototypes often correspond to an outdated state at the time of the workshops and thus make it difficult to optimally design the workplace. Furthermore, not all equipment variants and derivatives can be simulated in prototype workshops.

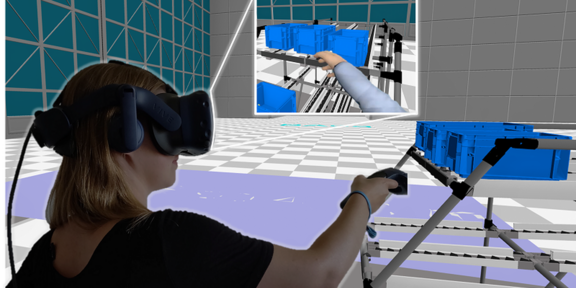

To meet these challenges and to accelerate the planning process, the IPS, together with a cross-brand project team, designs a virtual implementation of the described process workshops based on VR technologies. By means of VR, the participants are intended to be placed in a position to test and evaluate planned work processes without physical prototypes, independent of time and location. In order to ensure a targeted and efficient use of VR technologies in work system design, it is crucial to include both the technological conditions and the requirements set by workshop participants (e.g. IE) in the development process of the virtual workshop. This involves the conception, testing and effectiveness testing of usable tools, methodical procedures and virtual work environments. Based on the knowledge gained, the IPS derives the future work of the industrial engineer within the framework of a digitalized product development process and customer order process. In this course, additional tasks, competencies, responsibilities and qualification requirements are to be defined, piloted and implemented in the long term. With the help of the targeted use of VR there is a high potential to shorten the planning process and to increase the planning quality by virtual validation. Thus, ergonomic risks can be recognized in time, products can be designed proactively and measures for the motion-economical design of work steps can be planned and implemented earlier.

Translated with www.DeepL.com/Translator (free version)

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/3/3/csm_Maschinenbau-I_06d0e1956d.jpg)