Augmented-Reality-Demonstrator

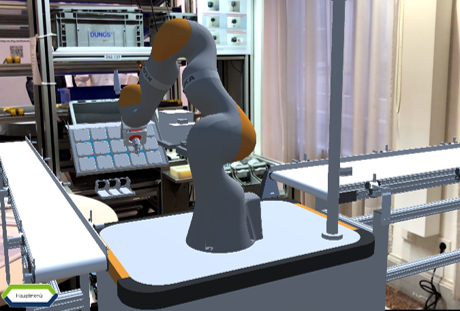

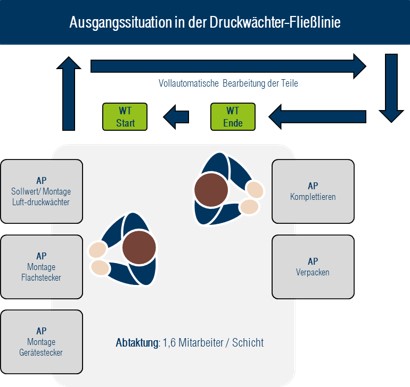

The AR demonstrator was developed as part of the KOMPI research project and is based on a workstation from a U-line for pressure switch production at the user company Dungs. This workstation was selected according to the planning systematics for human-robot interaction systems developed in the KOMPI research project and maps the MRI planning process from the selection of a suitable workstation to the digital cardboard setup including a virtual robot.

Hardware and Structure

The basic frame of the AR demonstrator consists of square aluminium profiles on which a workpiece carrier and various conveyor systems for material supply are mounted. In addition to the supply by crate, this is carried out via a chute for the base body of the pressure switch, several separation tubes, e.g. for nuts and sealing rings, as well as an automated screw separator. The assembly of the pressure switch is mechanised with the help of a torque-limiting rod screwdriver.

The core element of the AR demonstrator is the AR application for tablets that is part of the demonstrator, with the help of which the maturity of the workplace is displayed in the Quickcheck, also developed at IPS, and in which a robot is integrated into the system with the help of augmented reality, which carries out the work tasks corresponding to the work plan.

Application Scenarios in Research and Teaching

The aim of the AR demonstrator is to simulate MRI solutions during the planning process in order to detect weaknesses in the planning at an early stage and correct them accordingly. With the help of the demonstrator app, it is possible to simulate and validate the current planning status of an MRI solution using augmented reality (AR) functions during the planning process in the real production system. Along with this, it is also being investigated how assembly workers can be integrated into the planning process in the best possible way in order to build a new human-machine interface on the basis of a real production system.

The AR demonstrator is also already being used successfully in teaching and helps to clearly demonstrate the possible applications and benefits of MRI and AR to students.

Further Planned Application Scenarios

The next step is to investigate the extent to which AR applications can be integrated into assembly planning in an industrial environment and whether this integration helps to increase the acceptance of assembly workers towards MRI.

Funding notice:

The project is funded by the Federal Ministry of Education and Research as part of the funding programme "Innovations for tomorrow's production, services and work" on the topic "Assembly competence - collaborative and adaptable" and is supervised by the Project Management Agency Karlsruhe.