Conexing

Tool for interdisciplinary Planning and Product-related Virtual Optimisation of Automated Production Systems

Problem

The design of products, especially in medium-sized companies, is often strongly customer-oriented and individual; this applies both to products for the end customer and to the role as a supplier, which is particularly important for medium-sized companies. Shorter product life cycles and an ever-increasing number of variants are constantly increasing the demands and the need for innovative planning and simulation systems in order to make products available to the market promptly and efficiently.

The functional design of production facilities and their time- and cost-optimised realisation are only possible through the support and consolidation of all those involved in the entire product development and production process. The simulation and programming systems currently available usually only consider part of the overall process, and there is also a lack of data consistency. The systems used are often too complex on the one hand, and on the other hand they do not cover the entire path to complete virtual commissioning. The time-consuming and at the same time error-prone data conversion and system change steps therefore limit the usefulness of the available systems.

Objective

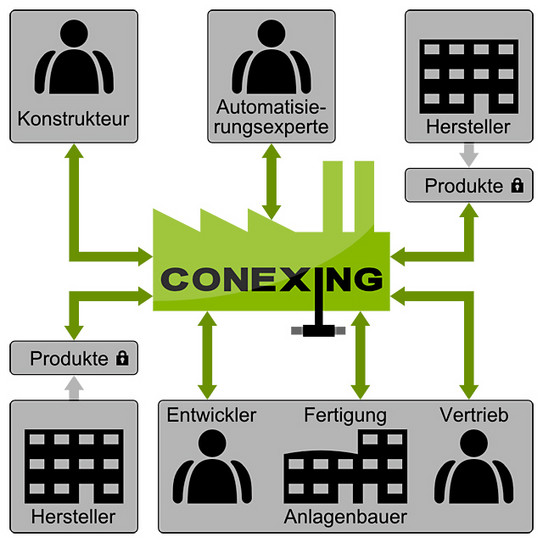

The aim of the project is to bring together all experts involved in the overall process in an interdisciplinary and cross-company manner from the conception phase to virtual production testing in a common working environment - the conexing solution. This tool must offer a new form of collaboration in terms of adaptability to future product and production scenarios and also create new possibilities in terms of usability and knowledge exchange. This favours broad acceptance and thus offers the best prerequisites for reducing the time and financial expenditure.

The illustration shows the vision of the project with the exemplary available components "robot", "sensor" and "gripper" for automated production within the conexing solution to be created: The product itself is discussed jointly by experts from the manufacturing and sales side as well as with automation experts in an interdisciplinary manner in addition to the production environment.

Procedure

This is to be achieved with an infrastructure that is secure in terms of access and data, the conexing solution, in which software systems, production resources and product data are made available by the manufacturers in a decentralised manner with their real behaviour. conexing opens up holistic use at any time, from planning to implementation to subsequent diagnosis of production. After verification, the conexing solution is opened to all interested parties: Component manufacturers make their products available, plant engineers select suitable components together with their clients and test them in now realistic virtual production environments in interaction the continuous virtual engineering up to commissioning becomes reality.

With conexing, KMUs are able to meet the increasing demand for simulated plants, driven by a shorter time-to-production, by using their implemented systems more efficiently.

The exploitation of the solution is carried out by the operators in the form of services and through the marketing of the rights to use the software. By using it, the users benefit from the increase in efficiency and the equipment suppliers from the positioning of their components. The results offer new perspectives for teaching programmes.

The methods and data formats developed are transferable to all simulation-based engineering tasks. The results of the research work are published regularly and continuously documented through an internet presence.

Research- and Development Partner

ICARUS Consulting GmbH

SCHUNK GmbH & Co. KG

Daimler AG

SICK AG

robomotion GmbH

IBG Robotronic GmbH

Link & Link Software GmbH & Co. KG

RIF e.V.

Funding Reference

This research and development project is funded by the Federal Ministry of Education and Research as part of the BMBF programme "Research for the Production of Tomorrow" and is supervised by the Karlsruhe project management organisation.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)