ErgoKom

Development and Technical Integration of an Assessment Methodology for Determining Employee Stress in Order Picking Systems (ErgoKom)

(Project duration: June 2012 to February 2014)

Problem

Due to increasing cost pressure, shortened product life cycles and a growing number of variants, companies are forced to increase the value-adding part of their processes as well as the flexibility in production and logistics in order to maintain their competitiveness. The separation of production and logistics activities and the resulting increase in short-cycle processes, as well as the trend towards larger logistics areas, lead to an increase in the physical strain on employees in logistics and especially in order picking.

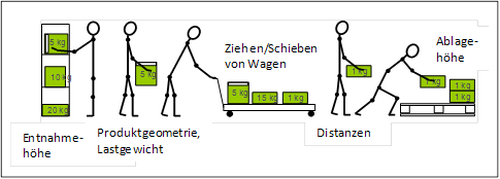

At present, there are only a few suitable methods for recording cause-effect relationships between the picking-specific influencing variables shown as examples in Figure 1 and their health effects on the musculature, the skeleton and the cardiovascular system of the employees. Due to this, the development of a low-effort assessment methodology for the continuous and detailed mapping of identified cause-effect relationships as well as for the analysis of the level of stress in practical picking scenarios is imperative.

Objective

The aim of the research project, which is being carried out in cooperation with the Chair of Materials Handling, Material Flow and Logistics (fml) at the Technical University of Munich, is to develop a specified and low-effort methodology for analysing, evaluating and visualising the physical stresses that occur in order-picking systems, taking into account recognised work analysis procedures. Furthermore, the assessment methodology is to be technically implemented and prototypically implemented in a selected, representative order picking system. The intended research results are to ensure the long-term employability of the employees. In addition, companies will be enabled to design their logistics processes in an optimal and value-creating way and to positively influence the stress situation in order-picking systems in a prospective manner. This results in a reduction of occupational illnesses and the prevention of long-term health damage.

Procedure

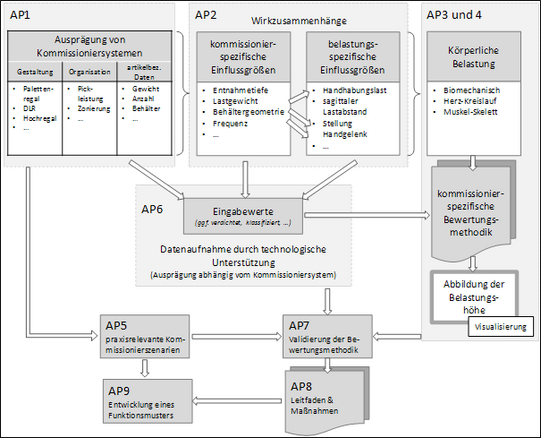

The general approach of the research project and the relationship between the work packages required for this can be seen in Figure 2. The starting point of the research activities is the analysis and classification of typical characteristics of order picking systems as well as the determination of order picking-specific influencing variables that are related to physical strain. Taking into account existing studies, such as existing dose models and biomechanical human models, load-specific influencing variables are also to be recorded and presented in a structured manner. Based on this, the interrelationships between the two categories will be identified and explicitly shown. Based on the research results obtained, it is necessary to implement a low-effort evaluation method for recording and visualising the load level, depending on the identified picking- and load-specific influencing variables. For this purpose, work analysis methods currently used in the industry and available in the literature are to be analysed and evaluated with regard to their suitability for use in order-picking systems on the basis of various test criteria, such as execution effort and type of input and output variables.

In a further step, on the one hand, representative picking scenarios from practice are to be selected, which reflect the different forms and characteristics of stress. Secondly, technical concepts for the continuous recording and visualisation of the load are to be developed. Possible solutions in this context are the use of industrial sensors (RFID or light barriers) or motion capturing, which is used for movement analysis. In addition to technical integration, it is necessary to examine individual output media with regard to their practicality and economic viability. Solution variants include stationary or mobile monitors or data glasses.

To validate the methodology, it will be implemented in a suitable picking system. In this context, the results achieved (e.g. load levels, risk classes) are to be compared with those of existing procedures. Furthermore, additional starting points for the optimisation of the assessment methodology are to be developed by means of the intended cooperation with experts from occupational health and safety and work system design as well as the questioning of employees.

Finally, a guideline is to be developed for the comprehensive documentation of the assessment methodology, which will be used in the future as a basis for the ergonomic design of order picking scenarios. In addition to a detailed description of the methodology, this guideline should also include special features of the evaluation with regard to the interpretation of the results and the derivation of individual improvement measures. Furthermore, the results obtained during the research project are to be depicted in a functional model.

Research- and Development Partner

Funding Reference

The research project (Research Project No. 440 ZN/2) is funded from the budget of the Federal Ministry of Economics and Technology via the German Federation of Industrial Research Associations "Otto von Guericke" e.V. on behalf of the Federal Logistics Association.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)