HaptoBot

Robot-assisted End-of-Line Testing of Haptic Characteristics for Quality Control

Problem

The human-machine interfaces in our environment are increasingly not only trimmed for flawless functionality, but should also convey an impression of quality that is appropriate to the overall product. This is referred to as "look and feel". In the context of quality control, it is therefore of particular importance to objectively record and evaluate the desired haptic characteristics. A robot system in combination with highly sensitive sensor technology offers the necessary flexibility, precision and reproducibility to reproduce complex human operating actions and to record them metrologically.

Objective

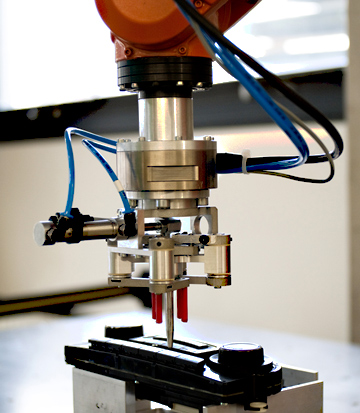

As part of the HaptoBot project, a standard industrial robot is to be equipped with a real-time force control system and a high-resolution force-torque sensor. The robot is used to carry out the test movements on the switching element and simultaneously to record the operating forces. In addition, the measured force and torque values are to be used to actively correct the position and orientation of the measuring device. In this way, interference caused by positioning errors or component tolerances can be reduced. The overall goal of the robotics is to record error-corrected haptic characteristics at high speed and with minimal teaching effort.

Procedure

First of all, the necessary human operating actions are to be simulated by means of industrial robots. This requires the development of a flexible actuation component. The test movements are to be defined by force and torque threshold values in order to keep the teaching effort low and to compensate for differences between the individual test objects. During the test movement, automatic compensating movements of the robot should reduce any disturbances in the measured values, for example due to position-related lateral forces. A particular challenge here is the very small actuation forces, which place high demands on the measuring equipment and the guidance by the robot. Another component of the sub-project is to enable the programming of the test station and the test sequences in a description that is close to the application, so that operation is not difficult even for users without special robotics knowledge.

- Video: Test set-up and execution procedure MP4 (9 MB)

Funding Reference

The ZIM project HaptoBot is funded by the Federal Ministry of Economics and Technology through the AiF as part of the programme "Central Innovation Programme for Medium-sized Enterprises" on the basis of a resolution of the German Bundestag.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)