Inforob

Modular system-independent training model for innovative advanced training in robot applications for medium-sized enterprises

Problem

The spread of industrial robots in production today shows great inhomogeneity across all branches of industry. In addition, the use in the different companies is characterised by a high degree of diversification, whereby robots have already been used for some time in the automotive and automotive supplier industry in particular. However, the use of industrial robots is often limited to larger companies, while medium-sized enterprises install robots much less frequently.

The comparatively low use of robotics in KMUs so far is mainly due to the fact that there are no employees available in the companies who are trained in this technology. The employment of suitable personnel generally fails, on the one hand, due to the insufficient supply of suitable skilled workers on the labour market and, on the other hand, due to the fact that the scope of the work involved is often too small to justify the permanent employment of a specialist. Purchasing programming services from system houses is not always an economical solution either. In addition to the necessary time coordination, costs are also incurred. But above all, it limits the company's flexibility if no one in the company is able to carry out minor adjustments. Another approach is to train existing staff. Taking into account staff absences, e.g. due to holidays or illness, it makes sense to train at least two people in the company. The costs incurred and the downtime due to external training often make these solutions unattractive. In addition, in KMUs the existing robot systems usually have to be reprogrammed comparatively often. However, in comparison to large companies, only a few systems are available. For this reason, the individual system is reprogrammed more often for a new product, but overall the personnel only sporadically have the opportunity to use and deepen the knowledge they have learned in practice. Due to the infrequent occupation with the problem, some of what has been learned is forgotten, which in turn leads to problems in dealing with the complex robot systems.

Objective

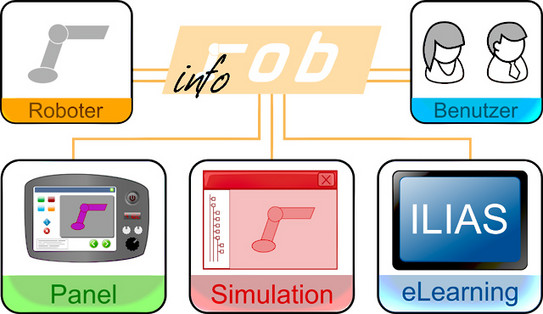

The aim of this project was to create possibilities to counter this problem and to make the training of the staff more efficient. The robot as an explainer of its mode of operation supports the staff in learning the subject matter from the very beginning by presenting important elements of robot handling and programming. In this way, a tutorial presented by the robot, as is already frequently used in software systems, should help the staff to quickly understand and learn the handling and technology of a robot already with the first modules. By describing and explaining various training contents (e.g. modules for commissioning, for programme management, for coordinate systems or also for troubleshooting), the operator is to be made more familiar with the way the robot works, thus enabling efficient operation of the robot-supported system with regard to troubleshooting, adjustments and optimisations. Furthermore, the staff can be additionally supported in the learning and refresher phase by means of displays and aids on the hand-held operating device.

- Ensuring consistency and freedom from redundancy in the overarching or multidisciplinary development process.

- Mastering the complexity of product development

- Shortening planning times by supporting simultaneous engineering and collaborative engineering.

- Ensuring the quality of planning and its results.

The management of time data plays a key role in the digital factory. Time data are decisive variables for the description of processes and represent an essential database of the digital factory. Due to their relation to both product development and production, time data become a connecting element in the data network of product creation. Despite the great importance of time data in product creation, there is a lack of concepts with which a computer-supported, efficient and continuous provision of time data is possible, especially in the planning phase of products. For this reason, the joint project ADiFa is working on the concrete and exemplary realisation of an application protocol for the exchange of time data. The goal here is to network the application area of time management with the other planning functions and areas of the digital factory. The basis for this is formed by consistently available time data, as shown in the following figure, which is specified via the application protocol for time management.

Procedure

- Creation of training content for various exemplary robot types

- Creation of a computer interface for learning and starting sample programs directly on the robot

- Creation of a handheld application to display training content and run sample programs directly on the robot

- Creation of a software application for linking training content with sample programs

- Integration and testing of the components in two training cells

Research- and Development Partner

Klero GmbH

Qualitus GmbH

Tropen Plastics Technology GmbH

Steinbichler Optotechnik GmbH

Funding Reference

The research project inFoRob - "Modular system-independent training model for innovative advanced training in robot applications for KMUs" was funded by the Federal Ministry of Education and Research and supervised by the Karlsruhe project management organisation.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)