OptiMilk

Mathematical modelling of in-plant milk run systems to optimise production-related material supply (OptiMilk)*.

(Project duration: August 2011 to July 2013)

Problem

In the course of an ever-increasing diversity of variants and ever-shorter product life cycles in the product structure of manufacturing companies, special requirements are placed on production logistics, especially just-in-time material supply for the line. The internal milk run principle currently practised in many companies is often a suitable solution in terms of minimum stocks and supply security.

However, current approaches only deal with the respective development stages and only optimise individual parameters on the basis of cost considerations.

For a continuous improvement of the internal material supply by means of milkrun within the framework of a continuous improvement process, it must be examined how a model must be structured conceptually and functionally, taking into account all influencing variables, in order to guarantee a lean and frequency-optimised provision of production.

Objective

The task is to develop a tool based on mathematical algorithms that determines a frequency-optimised delivery cycle depending on company-specific influencing variables (e.g. line frequency, container characteristics, personnel capacity, etc.). The sometimes interdependent parameters must be subjected to integrated optimisation in the course of this. This complexity should be taken into account in the model both qualitatively and quantitatively.

Procedure

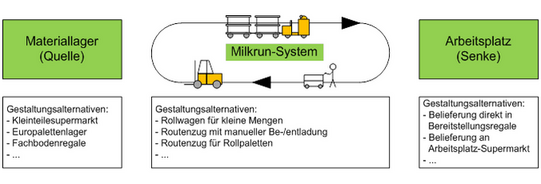

Since no practice-oriented instruments for production-specific material supply depending on systemically variable influencing variables have been researched so far, the research project aims to provide users with a tool that allows company-specific input parameters to flow into the optimisation of the in-house milk-run system. For this purpose, a mathematical model and a corresponding solution algorithm will be developed.

The model to be developed calculates a frequency-optimal supply of different workplaces or production islands. The general conditions and premises at the respective material sources and sinks are integrated into the calculation.

The result is a planning methodology for the rapid calculation of the optimal internal supply frequency, taking into account the prevailing production scenarios.

Funding Reference

The IRD project 17159 N of the research association Gesellschaft für Verkehrsbetriebswirtschaft und Logistik e.V. - GVB, Wiesenweg 2, 93352 Rohr is funded by the Federal Ministry of Economics and Technology via the AiF within the framework of the programme for the promotion of joint industrial research and development (IRD) on the basis of a resolution of the German Parliament.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)