SkalKomm

Scalable order Picking Systems

Development of a Set of Tools for the Selection of a Cost-Optimal Scalable Order Picking System Considering Predicted Workload Fluctuations

Problem

The requirements for order picking systems are increasingly changing due to the development of the market. The consequence of market changes is that customer demand behaviour is difficult to predict, as no past data is available for forecasting. The fluctuations in demand and market changes present order picking systems with ever new challenges in terms of throughput time and reaction speed with high item availability.

The biggest challenge in a picking system, besides reducing stock in the warehouse, shortening throughput time and minimising picking errors, is above all the economic operation of the picking system. Picking must be fast, reliable and at the lowest possible cost. The targeted adaptation of order-picking systems to changes in sales has so far only partly been the subject of scientific research approaches.

Especially in the short-term planning area, there is no systematic procedure to react economically and quickly to fluctuations in demand and market changes in order-picking systems. Individual measures are known and are used to some extent. A holistic view over several periods, in which, for example, short-term disadvantages can be accepted in order to achieve a long-term optimum, does not take place systematically.

Objective

Specifically for order picking in conventional order picking systems in SMEs, this research project aims to develop a decision model that supports SMEs in systematically and specifically adapting their company-specific order picking system to short-term fluctuations in demand and market changes. For this purpose, flexibility potentials in order-picking systems are to be identified and described in an operationally applicable way in the form of adaptation measures. To simplify the application of the research results, the decision model will be programmed in software.

The following central questions should be able to be answered within the framework of the research project:

- How can the available capacity in picking systems (picking warehouse, means of transport, human) be optimally adjusted to the capacity demand over several periods?

- Which adjustment measures are available to react economically to short-term fluctuations? Are different measures mutually exclusive?

- Which measures need to be taken at what point in time in order to commission economically over several periods, taking into account fluctuations in demand and market changes?

- How does the economic efficiency in order picking change when measures are implemented to adjust the capacity supply?

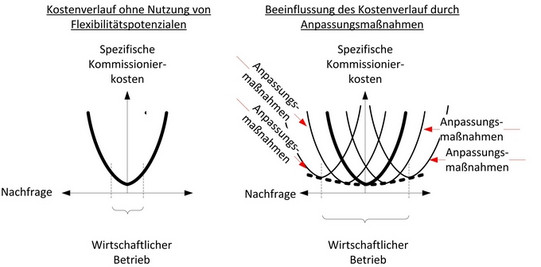

As a result, a contribution is made to the flexibilisation of picking systems that have the ability to achieve (almost) constant specific picking costs independent of the employment situation.

Procedure

The first step focuses on a detailed analysis of the current situation in SMEs with regard to the design of order picking systems and the effects of changes in sales on the order picking process.

For the cost-optimal design of order picking systems it is important to ensure sufficient transparency of costs. For this purpose, a cost analysis is carried out in order to identify cost focal points and to show cost developments over time. Overall, the cost level, the cost structure and the cost development of order picking systems are examined in this step.

In the next step, the relationship between costs, cost drivers and the utilisation of a picking system is examined. The aim is to describe this relationship mathematically. Adjustment measures are formulated for influencing the cost drivers. On the basis of the calculation rules determined in this way, cost curves are determined for an order-picking system depending on the forecast change in sales.

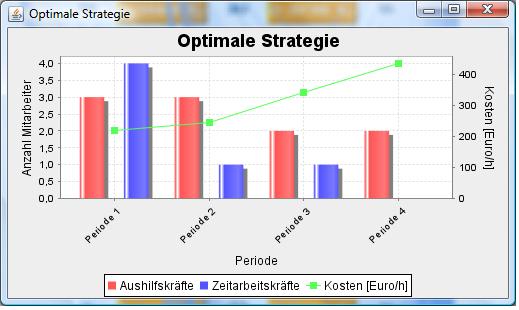

For the company-specific adaptation of the results, the calculation rules with adaptation measures are programmed in a software as a decision model. In this way, the input variables for the calculation can be adapted to the specific company and individual cost curves can be calculated for each company. Based on the decision model, the cost-optimal configuration (sequence of adjustment measures) of the order-picking system is then determined.

In order to provide all interested companies with easy access to the project results, the final report will be published on the internet.

Publications

- Scholl, P.; Deuse, J.: Optimale Personalstrategie in der Kommissionierung, Wt Werkstattstechnik online. Springer-VDI-Verlag. (www.technikwissen.de/wt/) (Genauer Veröffentlichungstermin noch nicht bekannt)

- Scholl, P.: Endbericht: Skalierbare Kommissioniersysteme, Herausgegeben von Jochen Deuse, Lehrstuhl für Arbeits- und Produktionssysteme, Technische Universität Dortmund. Dortmund, Oktober 2009

- Scholl, P.: Softwarekonzept zur Ermittlung von Kostenkennlinien bei schwankenden Auftragseingängen in Kommissioniersystemen, Vortrag an der Technischen Universität Dortmund. 29.05.2009

- Scholl, P.: Entwicklung von Flexibilisierungsstrategien für Kommissioniersysteme, Vortrag an der Technischen Universität Dortmund. 5.9.2008

Funding Reference

The research project (Research Project No. 15359 N) has been funded from the budget of the Federal Ministry of Economics and Technology via the Federation of Industrial Research Associations "Otto von Guericke" e.V.. (IRA) on behalf of the Federal Logistics Association (FLA).

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)