ViReBa

Development of a Vibration Cleaning Process for Industrial, Resource-Saving Component Cleaning

Problem

For industrial companies, industrial component cleaning has an important function in ensuring product quality. Large-scale washing systems, which are capital-intensive and usually positioned centrally in the factory, are used to remove chips, oil and cooling lubricant residues from machined semi-finished products. In most cases, these plants are designed for batch operation, so that high material stocks are tied up and small batch sizes are difficult to achieve. In addition, the conventional cleaning of workpieces from oils, cooling lubricants, chips and other contaminants, both by wet cleaning and by a special blow-suction technique, requires a lot of energy, water and space.

The novel method of vibration cleaning, which was developed by vibro-tec GmbH from Unna and patented by its founder Dipl.-Ing. Klaus Döhrer, represents an energy-efficient and resource-saving alternative to the conventional methods of component cleaning described above. Vibration cleaning is a dry cleaning process suitable for decentralised individual component cleaning, which uses vibrations to overcome adhesion forces, i.e. the adhesion of oils, emulsions and other contaminants. Low-energy vibrations loosen contaminants from the surface of the workpiece, allowing them to be easily extracted. The removed medium is not affected in its quality, so that it can be returned directly to the operating medium circuit. This reduces the costs for the use of media, the subsequent disposal and also protects the environment.

Objective

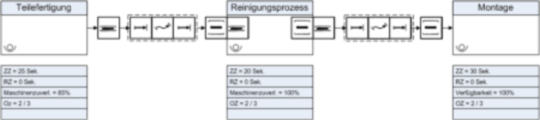

As part of the KMU-innovativ: Ressourcen- und Energieeffizienz (SME Innovative: Resource and Energy Efficiency) funding programme, the vibration cleaning technology is to be further developed for its use in industrial series production. The focus is on both the development of cleaning technology suitable for series production and its integration into lean production lines à la Toyota.

In order to achieve this goal, two focal points are being worked on, which are considered to be very important for market success:

- Developing and testing constructive solution options for expanding the product spectrum to be cleaned, improving the cleaning quality through simulation support and optimising the set-up processes resulting from an expanded product spectrum.

- To develop and test potential handling and conveying systems to ensure improved integrability of the vibratory cleaning process into an existing work system.

In order to bundle expertise and exploit synergy effects, the companies vibro-tec GmbH and Neuhäuser Magnet- und Fördertechnik GmbH have joined forces with the Chair of Work and Production Systems and the Department of Machine Elements at the Technical University of Dortmund to form a consortium that is working on the project in intensive cooperation.

Procedure

As a basis for the following investigations, typical fields of application of vibration cleaning are first determined and their framework conditions analysed. In particular, the alternative process design for the preliminary, intermediate and final cleaning of components will be examined, since vibration cleaning allows fundamentally different process sequences in terms of technology and design. Associated partners will provide real-life application scenarios for necessary cleaning cases in order to obtain practical results and to be able to validate them on real systems.

For the purposes of the project, the product spectrum is limited to rotationally symmetrical or approximately rotationally symmetrical components and complex components, since a large part of the component spectrum to be cleaned is made up of these types.

The vibration generators and the clamping tools are to be further developed by means of design systematics. The aim is to develop tools that can grip workpieces over as small an area as possible and clamp several similar workpieces. Furthermore, interfaces to the vibration tooling are to be created that allow a quick and uncomplicated change. This is to be realised by a modularised suction jaw system, so that complete sets of suction jaws no longer have to be exchanged, but only individual suction elements.

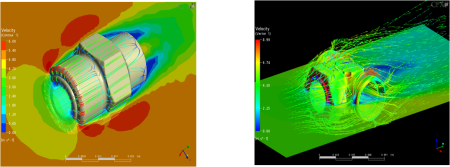

For the development of optimised suction tools and spray nozzles for the cleaning agent as well as clamping tools that can set the workpiece into corresponding vibrations, the vibration cleaning with its structural and flow dynamic boundary conditions is simulated. This is a so-called FSI problem (Fluid-Structure Interaction), in which on the one hand the vibration transmission and on the other hand the flow of the air stream or the cleaning medium are to be considered.

In order to verify the simulation results and implement them in a prototype, a test machine is to be set up with the help of which the corresponding tests can be carried out.

In order to be able to exploit the advantages resulting from the modular design of the modified and optimised vibration cleaning system for seamless integration into existing production concepts, handling concepts for component loading and subsequent forwarding to the next processing station are to be developed. The application scenarios developed in industry will be used as examples of possible applications. Depending on the industrial boundary conditions, there are different approaches to handling technology with varying degrees of automation.

Since the previous method of vibratory cleaning is predestined for a one-piece flow that is to be aimed for, corresponding handling systems and conveyor systems must be adapted to one-piece handling.

Publications

- Krebs, M.; Oeken, N.: Schlussbericht: Entwicklung eines Vibrationsreinigungsverfahrens für die industrielle, ressourcenschonende Bauteilreinigung (ViReBa), Herausgegeben von Jochen Deuse, (Lehrstuhl für Arbeits- und Produktionssysteme) und Bernd Künne (Fachgebiet Maschinenelemente), Technische Universität Dortmund. Dortmund, Januar 2011

- Krebs, M.; Deuse, J.:Parts cleaning in the value stream. In: Proceedings of 3rd International Conference on Changeable, Agile, Reconfigurable and Virtual Production (CARV 2009), 5.-7.10.2009, München, S. 800-809.

- Krebs, M.; Deuse, J.: Resource efficient and economic parts cleaning – Requirements oriented cleaning saves resources, energy and money, In: Proceedings of International Conference on Competitive Manufacturing (COMA ´10), 03.-05.02.2010, Stellenbosch, South Africa, S. 165-170.

- Krebs, M.; Schmitz, L.; Deuse, J.: Sustainable cleaning of parts. In: Quaderni della XIV Summer School "Francesco Turco" Impianti Industriali Meccanici: "Sustainable Development: The Role of Industrial Engineering", 15.-19.9.2009, Port Giardino, Italy, S. IV.139-IV.145.

- Krebs, M.; Richard, T.; Doehrer, K.: Weiterentwicklung der Vibrationsreinigung - Flexibel und sicher für Inline-Prozesse, JOT - Journal für Oberflächentechnik (2009) 5, S. 56-57.

- Deuse, J.; Doehrer, K.; Droste, M.: Enviromental and Economic Benefits of Vibration Cleaning, Proceedings of the 15th CIRP International Conference on Life Cycle Engineering. Sydney, 17.-19. März 2008, S. 634-639.

- Deuse, J.; Krebs, M.; Droste, M.; Doehrer, K.: Bauteilreinigung im Wertstrom, ZWF - Zeitschrift für wirtschaftlichen Fabrikbetrieb 103 (2008) 9, S. 598-601.

Research- and development partner

Department of Machine Elements (ME), Dortmund University of Technology

vibro-tec GmbH, Unna (SME)

Neuhäuser Magnet- und Fördertechnik GmbH, Lünen (SME)

Funding Reference

This research and development project was funded by the Federal Ministry of Education and Research within the funding programme " SME-innovative: Resource and Energy Efficiency" (funding code 0330862B) and supervised by the project management organisation at Research Centre Jülich GmbH (PtJ).

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)