SUPPLy

SimUltane Product and Process Development of a Charging Station Outlet Module Suitable for Automation

Problem and Motivation

Due to current developments in the context of the energy transition and the new climate policy framework conditions, electromobility is one of the efficiency technologies of the future. This poses new challenges, especially for the automotive industry in Germany and all related industries.

The goals set by the German government with regard to electromobility can only be achieved by ensuring a nationwide charging infrastructure. A strong increase in the number of electric vehicles therefore requires a correspondingly extensive provision of suitable charging stations.

This development is currently still at an early stage. The comparatively low demand for charging stations means that manufacturers are reluctant to make extensive investments in automation solutions. In addition, automated production cannot be implemented due to the current technological design of the charging stations. Therefore, the assembly of charging stations has so far been carried out mainly manually. However, with the significant increases in unit numbers that are forecast, it is to be expected that manual production will quickly reach its limits.

Objective

Due to the problem described above, the overall objective of the SUPPLy research project is therefore the development of a continuous, digital and simultaneous product and process development of a modular charging station suitable for automation. In addition to the development of the technological product design, this includes the conception of a robust, scalable manufacturing process through the consistent use of digital tools.

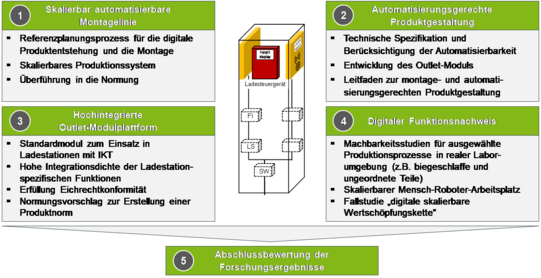

For the conceptual design of a new type of assembly system, the complete value chain of a charging pole is considered; the improvement of individual existing process steps does not lead to the goal. Figure 1 shows the resulting five sub-goals of the project.

Procedure and Division of Labour

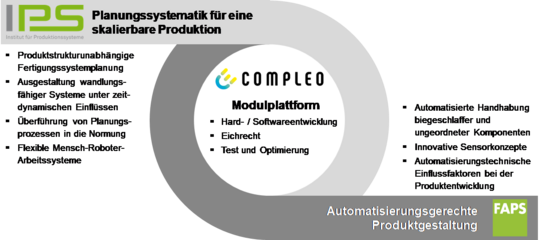

The project consortium is interdisciplinary and, in addition to the Institute of Production Systems (IPS) at the Technical University of Dortmund, includes the Chair of Manufacturing Automation and Production Systems (MAPS) at the Friedrich-Alexander University of Erlangen-Nuremberg and Compleo Charging Solutions GmbH, a manufacturer of charging stations. The aforementioned members are pursuing a three-dimensional solution approach (see Fig. 2).

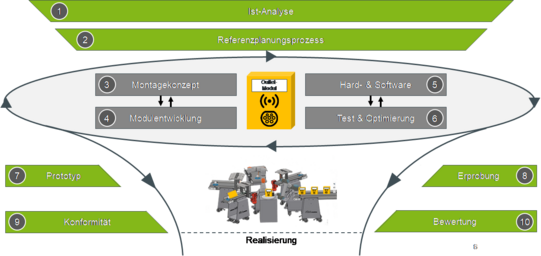

The product development of the outlet module is the responsibility of Compleo Charging Solutions GmbH. The focus of the MAPS chair is on the development of automation-compatible processes in addition to the requirements for automation-compatible product design. The IPS coordinates the development of a scalable, automatable production concept. This sub-project is divided into the following ten work packages (see Fig. 3).

Another sub-goal of SUPPLy is to transfer the developed reference planning process into an industrial standard in order to generate a high level of dissemination. The topic of unit-dependent automation concepts is also being prototypically investigated under laboratory conditions and subsequently optimised and validated in a practical manner in a real test environment. The results of the research project will be published in various journals, presented at conferences and incorporated into university teaching. The publication of the results is additionally promoted through close cooperation with industry networks.

Research-, Development- and Application Partners

Funding Reference

This research and development project is/was funded by the Federal Ministry for Economic Affairs and Energy in a joint funding initiative to promote research and development in the field of electromobility (funding code 01MV19001B) and is supervised by the German Aerospace Center project management organisation.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)