Completed Research Projects

Below you will find an overview of the already completed projects of the IPS.

Networked and Integrated Application of Industrial Data Analysis for Value-Creating, Competence-Oriented Collaboration in Dynamic Value Networks

Concept for the development of machine learning competencies for plant manufacturers and manufacturing SMEs

(Project processing is carried out by RIF e.V., Production Systems Department)

SimUltane Product and Process Development of a Charging Station Outlet Module Suitable for Automation

Prediction of dynamic bottlenecks in aligned material flow systems using Machine Learning

(Project processing is carried out by RIF e.V., Production Systems Department)

Autonomous quality control using machine learning methods

(Project processing ist carried out by RIF e.V., Production Systems Department)

Systematic use of exoskeletons in production and logistics

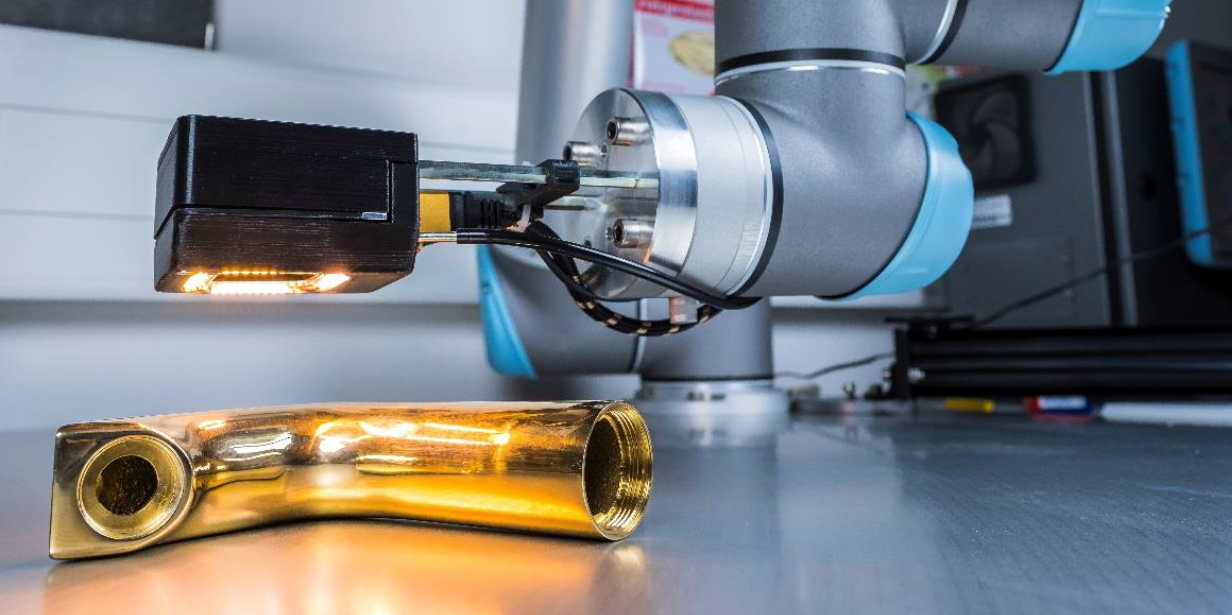

System for adaptive phototonic surface testing with adaptive image evaluation in combination with a cleaning system

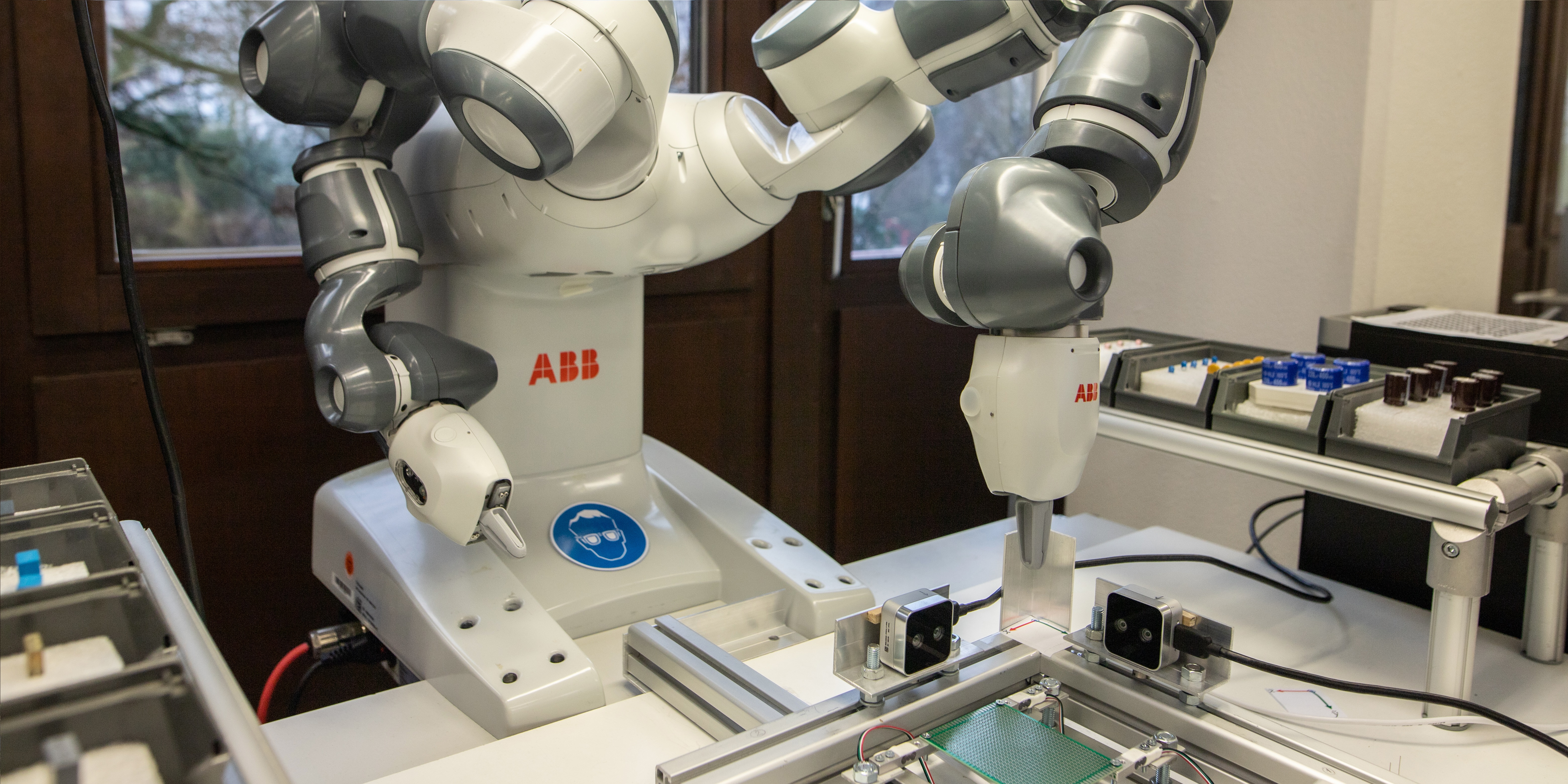

Development of a novel self-learning gripper system and adaptation of reinforcement learning algorithms as extension of existing lightweight robots for flexible PCB assembly using Through Hole Technology (THT)

Equipment behaviour catalogues for virtual production systems

(Project processing is carried out by RIF e.V., Production Systems Department)

Utilization of digital twins for efficient control of recycling processes in the use-case of refrigerating appliances recycling

(Project processing is carried out by RIF e.V., Production Systems Department)

Open association of industry, research, carbon sink operators and software operators creating an ecosystem to address the current and future challenges of product-related decarbonization.

(Project processing ist carried out by RIF e.V., Production Systems Department)

Quality control in additive manufacturing of copper materials by predicting material and component properties using machine learning

Cross-Process Chain Detection of Material and Process Anomalies in Imbalanced Data for Engineering Plastic Assemblies

(Project processing ist carried out by RIF e.V., Production Systems Department)

Predictive sales and demand planning in order-based manufacturing using machine learning methods

(Project processing ist carried out by RIF e.V., Production Systems Department)

2nd Machine Learning and IoT Summer School in Cyber-Physical Brewing Lab

Prognosis-based competence evaluation

(Project processing ist carried out by RIF e.V., Production Systems Department)

Human-centered Execution Analysis of Manual Movement Patterns using Motion Capturing and Artificial Intelligence

(Project processing ist carried out by RIF e.V., Production Systems Department)

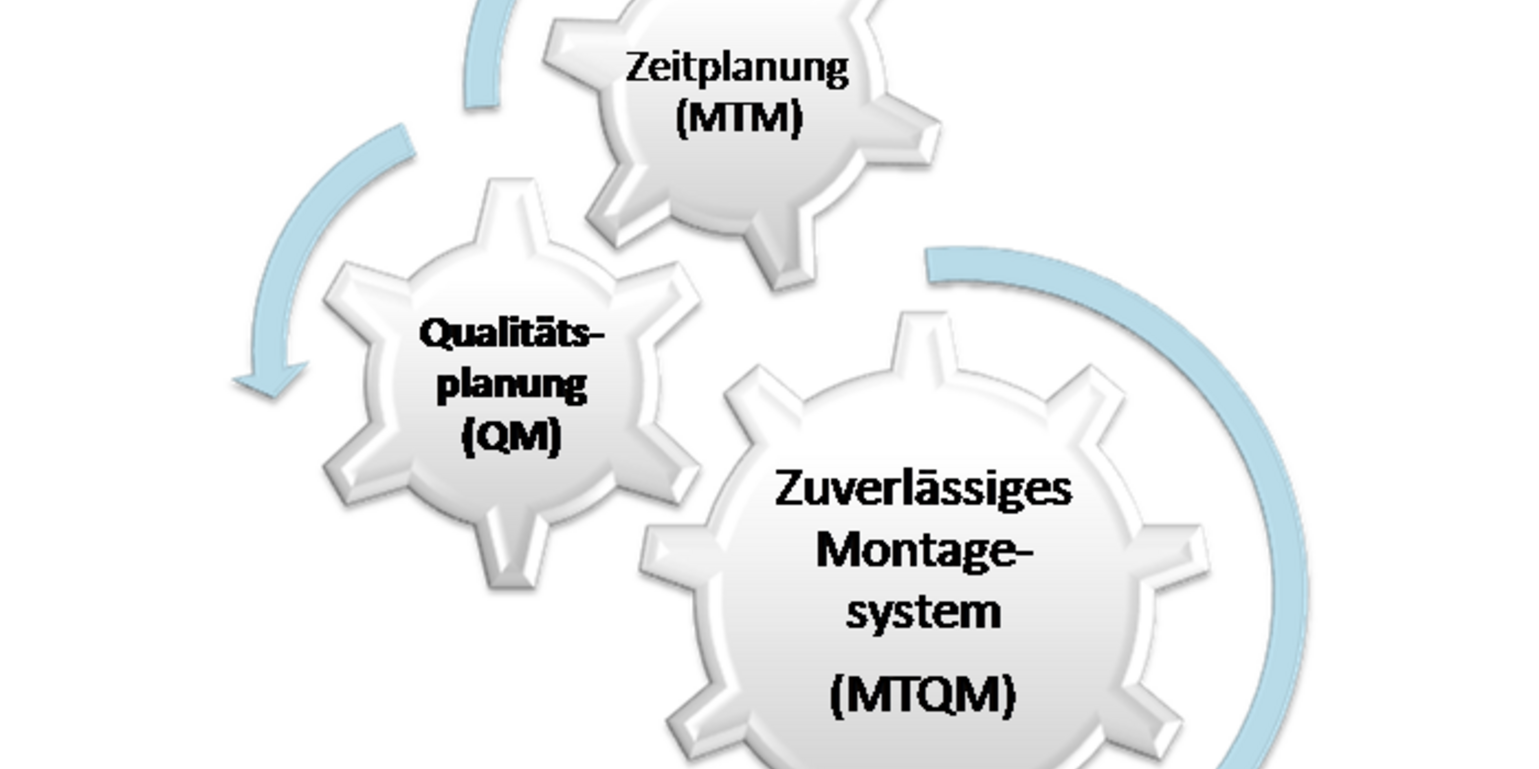

Simplification of the MTQM procedure for low-threshold applicability in SMEs

(Project processing ist carried out by RIF e.V., Production Systems Department)

Acceptance and Effectiveness of Exoskeletons in the Construction Industry

(Project processing ist carried out by RIF e.V., Production Systems Department)

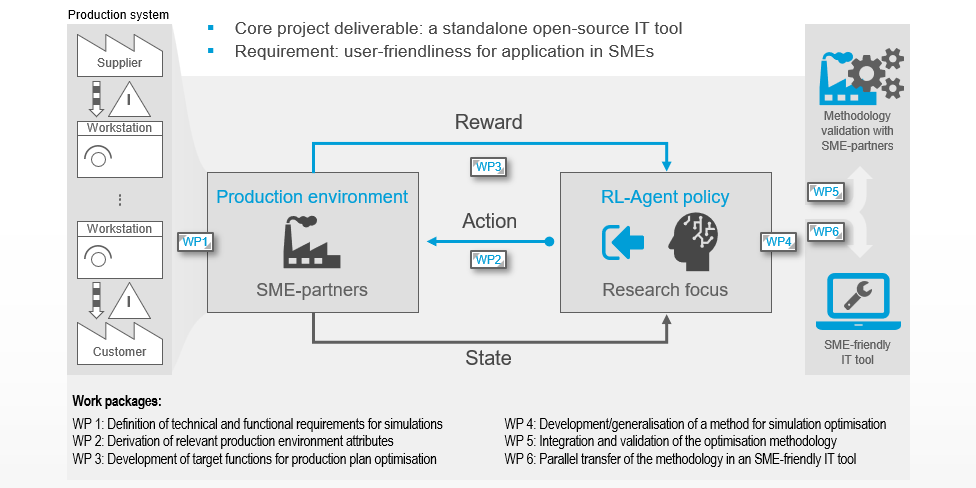

Operative Produktionsprogrammplanung durch selbstoptimierende Materialflusssimulation mittels Reinforcement Learning

(Projektbearbeitung erfolgt durch RIF e.V., Abteilung Produktionssysteme)

- ADiFa

The aim of the joint project is the further development and standardisation of a reference planning process for digital product creation. In a first step, this is to be manifested as a DIN draft and then lead to an international ISO standard. This standardisation is intended to achieve a higher level of commitment for manufacturing companies. - AgileKMU

The aim of the research project is to develop a digital platform for cross-company cooperation in the agile design of production systems. The division of planning tasks into sprint meetings will be extended beyond previous boundaries to enable these short-cycle and integrated methods in distributed engineering as well. The platform to be developed should enable the provision of planning data and processes and integrate digital workflow management, which can be used to support the company's internal process organisation. Agile collaboration is supported by the targeted provision of planning data and a flexible visualisation concept. - AGMASS

The aim of the cooperation project is to develop an automatic "gripping cell for solid forming" based on existing basic technologies, to test it in an industrial environment and to optimise it for series use in solid forming. The sub-goals are to make the "grip in the box" technology ready for application and process-safe for the field of solid forming, to make the possibilities and limits transparent from the point of view of the part geometries and the pours and to sound out the application potentials "after the grip" and to evaluate them technically/economically. - AIM

The aim of the research project is to develop a new component of occupational health management (OHM) for the long-term preservation of the adaptability and employability of employees. The targeted sensory, cognitive employee support through a work assistance system at an already designed workplace is of essential importance here. The central aspect of the new component of occupational health management is the linking of ergonomic and structural work design with competence and personnel development. - AuGeEn

Within the project, a system for the automated production of abrasive belt nests (belts inserted into each other as a packaging unit) is to be developed, which above all takes into account the flexibility requirements with regard to the different abrasive belts as well as the productivity requirements with regard to economic and technical parameters. The principle of nesting developed at the University of Dortmund is to be further developed and made ready for the market. In addition to a constructive design and optimisation of the actual nesting principle into a modular and flexible system, this requires the integration of further functions such as buffering and quality control. - AutoEdge

The aim of this project is to establish a targeted edge preparation by the beam cutting process for the flexible machining process-specific adjustment of the edge shape of complex cutting tools and the integration of this process into the industrial production chain. - Challenger

The project goal is the development of a sensor-, virtual- and robot-assisted therapy station for the treatment of movement disorders of the upper extremities. - CLean

The research project "Cross-value stream design of component cleaning concepts (CLean)" will start in April 2016 with the aim of designing a holistic system for analysing cleanliness-critical value streams as well as for designing and evaluating the integration and organisation of component cleaning systems. - Conexing

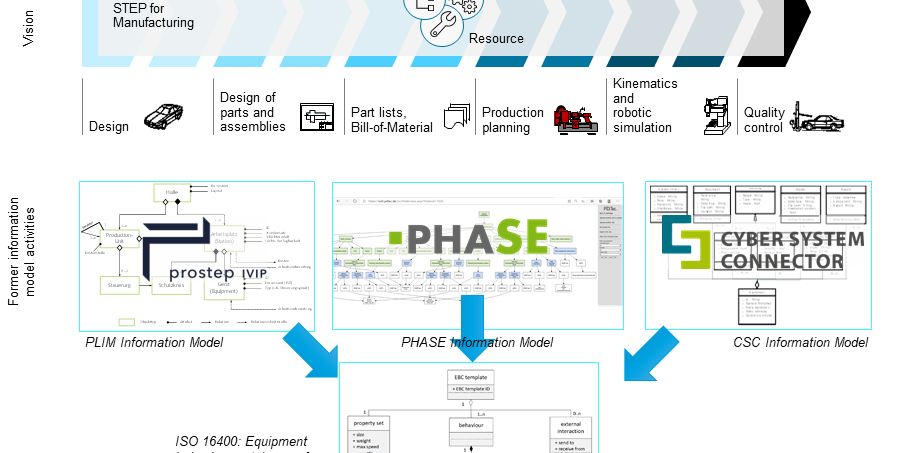

The aim of the project is to bring together all experts involved in the overall process in an interdisciplinary and cross-company manner from the conception phase to virtual production verification in a common working environment - the conexing solution. - Cyber System Connector

The aim of the CSC research project is to ensure up-to-date technical documentation by means of a virtual image of the systems throughout the entire product creation process. The CyberSystemConnector (CSC) forms the interface for each integrated system component of a machine and plant. Every change to the system, and thus to the technical documentation, is fed back into a virtual image of the system. Thus, there is always an equivalent virtual image of the real system. - CSR

The aim of "Change pro CSR" is the systematic and gradual anchoring of the values of CSR in the corporate management and culture of small and medium-sized companies from the metal, mechanical engineering and industrial electronics sectors of the Network Industry RuhrOst (NIRO). - DAPRO (project processing is carried out by RIF e.V.)

The aim of the DaPro research project is to develop a modular reference architecture for collaborative data use in the beverage industry to enable data-driven process optimisations. The close cooperation between users, machine and plant manufacturers enables the development of innovative, data-driven process optimisations and promotes the digitalisation efforts of the process industry. The focus is on the development of a toolbox of data mining modules and an IoT reference architecture for the beverage industry. In parallel, exemplary use cases are defined and implemented at the application partners. These practical examples enable the construction of specific analysis modules and the validation of created solution patterns. - EOP

The aim of the research project is therefore to support the selection of a cost-optimised strategy for post-series production or stockpiling of spare parts after the end of production. The starting point here is the integration of spare parts requirements into the current production in order to be able to use the existing production environment and thus synergy effects. - ErgoKom

Development of a specified and low-effort methodology for the analysis, evaluation and visualisation of occurring physical stresses in order-picking systems, taking into account recognised work analysis procedures. - GPS für LDL

In view of the increase in the range of services offered by logistics service providers and the spread of GPS in manufacturing companies in numerous sectors and value creation stages, the primary objective of the research project is to intensively penetrate the effects of these developments in order to develop an adapted GPS reference model for logistics companies on this basis. - Hands on IE!

The academic IE education at the Chair of Work and Production Systems pursues the goal of teaching students the theoretical basics of work system design and to deepen these in an industry-related context in an application-oriented manner. - HaptoBot

Within the scope of the project, a standard industrial robot is to be equipped with a real-time capable force control and a high-resolution force-torque sensor. The robot is used to carry out the test movements on the switching element and at the same time to record the operating forces. - HoQaB

High-speed quality inspection for sheet metal outer skin components - InDaS

Industrial Data Science - Qualification Concept for Machine Learning in Industrial Production - INDIVA

Individualised socio-technical work assistance for production - Inforob

Modular system-independent training model for innovative advanced training in robot applications for KMUs - The robot as an explainer of its mode of operation supports the staff in learning the subject matter from the very beginning by presenting important elements of robot handling and programming. - InnoLern

The goals of the InnoLern project can be differentiated company-related and network-related. On the company-related level, operative employees of the participating companies are trained in modern methods of industrial engineering and project management according to their needs. On the network level, the operative employees are systematically networked and the knowledge transfer between the companies is stimulated. - IRW

The aim of the IRW project is to show KMUs new ways and opportunities through innovative strategies so that they can keep pace with the competition and face global competition positively and confidently. The main task of the chair, which is active in the sub-area of production, is to support KMUs in improving their production processes and to achieve a long-term increase in market shares through the use of new forms of organisation in production. - KoMPI

The aim of the planned research project is to develop a new method for the integrated planning and realisation of collaborative workplace systems in assembly with variable product scenarios. This should ensure that even companies with little experience and limited resources are enabled to successfully introduce collaborative work systems and to operate them economically in the long term, even with a strongly fluctuating variety of products and variants. - Lasercut

Component-independent fixture for robot-assisted laser cutting - MANUSERV

From the manual process to the industrial service robot; planning, decision support and realisation of service robotics applications in the industrial environment. - MicroBatchFlow

Development of flow concepts in the assembly of small series with a large number of variants, taking into account technical and economic aspects - ModuLIT

The focus of the course to be created was on the design, maintenance and programming of automation systems, with particular consideration being given to the use and programming of industrial robots and the necessary peripherals. The learning contents are modular and can be worked on largely independently of each other. Due to the complexity of the subject, the learning process is simplified and supported by a realistic simulation of technical processes. - NED

The aim of the research project is to achieve network-wide excellence in the field of demographic change in NRW. The results of the project will be used to develop an efficient demography excellence programme (EPD) for small and medium-sized enterprises to cope with demographic change for KMUs in NRW. - Neue Formen von Industriearbeit

Empirical basis of the project are in-depth case study analyses in selected production sites of different companies. - NiVaK

The aim of the research project is to develop a systematic approach to production levelling in multi-variant small batch production, where the framework conditions for implementing conventional levelling concepts are generally not given. - OptiMilk

The task is to develop a tool based on mathematical algorithms that determines a frequency-optimised delivery cycle depending on company-specific influencing variables (e.g. line frequency, container characteristics, personnel capacity, etc.). - PHASE

The aim of the research project is to develop an approach for setting up cyber-physical machines for individualised manufacturing and assembly. To this end, research results from the fields of CPS and cloud technology are being integrated into an international IoT solution as part of the German-Korean cooperation "Manufacturing and Assembly as a Service (MAaS)". On this basis, new services will be introduced for the PDTec company in connection with the personalised delivery, rental and operation of modular production systems. For the validation, application scenarios are implemented on the Korean and German side both on the shop floor level and in the service layer. - Powergrind

The aim is to fundamentally further develop an essential component of the tool, the contact wheel, with the aim of significantly increasing the stock removal rate in robot-assisted belt grinding and thus improving the economic efficiency of belt grinding processes. - Pro Mondi

The development of a method for the prospective determination of assembly work content in an early phase of the product development process (PEP). The solution pursued here is based on a combination of the research fields of product data technology, the digital factory, data mining and time management in order to make cross-domain planning knowledge from different PEP phases available along the product creation process. - QU4LITY

The research focus of the IPS is the development of interoperable digital infrastructures for ZDM by exploring industrial applications of data analysis. An essential aspect of consideration is the reduction of error costs of automatic process control by reliably anticipating the resulting product quality already during the production process. On the basis of the anticipated product quality, action measures are to be derived for the subsequent production process, so that the test efficiency is increased in the entire value stream. The latter objective requires the development and integration of virtual sensors in the production processes to ensure detailed and at the same time digital documentation. - ReiMaFlu

Material flow systems suitable for cleanliness - development of a guideline for the design of material flows suitable for cleanliness along the value stream - ReProDiPro

The aim of the joint project is the further development and standardisation of a reference planning process for digital product creation. In a first step, this is to be manifested as a DIN draft and then lead to an international ISO standard. This standardisation is intended to achieve a higher level of commitment for manufacturing companies. - ReProInPlan

Reference process for integrated production planning - preparation for standardisation of information flows and planning key figures - Roboforming

The Institute for Robot Research at the Technical University of Dortmund (IRF) provides the basic principles for the information technology generation of the robot programmes based on CAD data. In addition to the two research institutes, the Industrieverband Blechumformung e.V. (Industrial Association of Sheet Metal Forming) is also responsible for the project. (IBU), with the help of its competence network, is also responsible for the dissemination of the results in addition to the transfer of knowledge for the benefit of collaborative project partners and association members. - Roprof

The key components of the development are a new mechanical design of the robot system that precisely meets the requirements of steel construction companies, automatic robot programming for "learning" new welding tasks in a matter of seconds, and sensor technology that reliably enables the robot to recognise and compensate for the large structural inaccuracies that are common in steel construction. - rorarob

Welding task assistance for pipe and frame constructions by a robot system" Development of an industrially applicable system that focuses on the interaction between humans and robots. - SafeGrip

Based on a previously defined process safety, a modular system selection, i.e. composed of components that can be combined with each other, is initially developed for an application in pharmaceutical laboratory operation. - SFB 696

In twelve sub-projects, one of which is being carried out at the University of Wuppertal, the aim is to place the current and future requirements of users, including product-related service, more firmly at the centre of the product development of intralogistics systems. The vision is to create the methodical and technical basis for flexible intralogistics systems that automatically react to changes, check themselves and repair themselves. - SFB 708 - Subproject A4

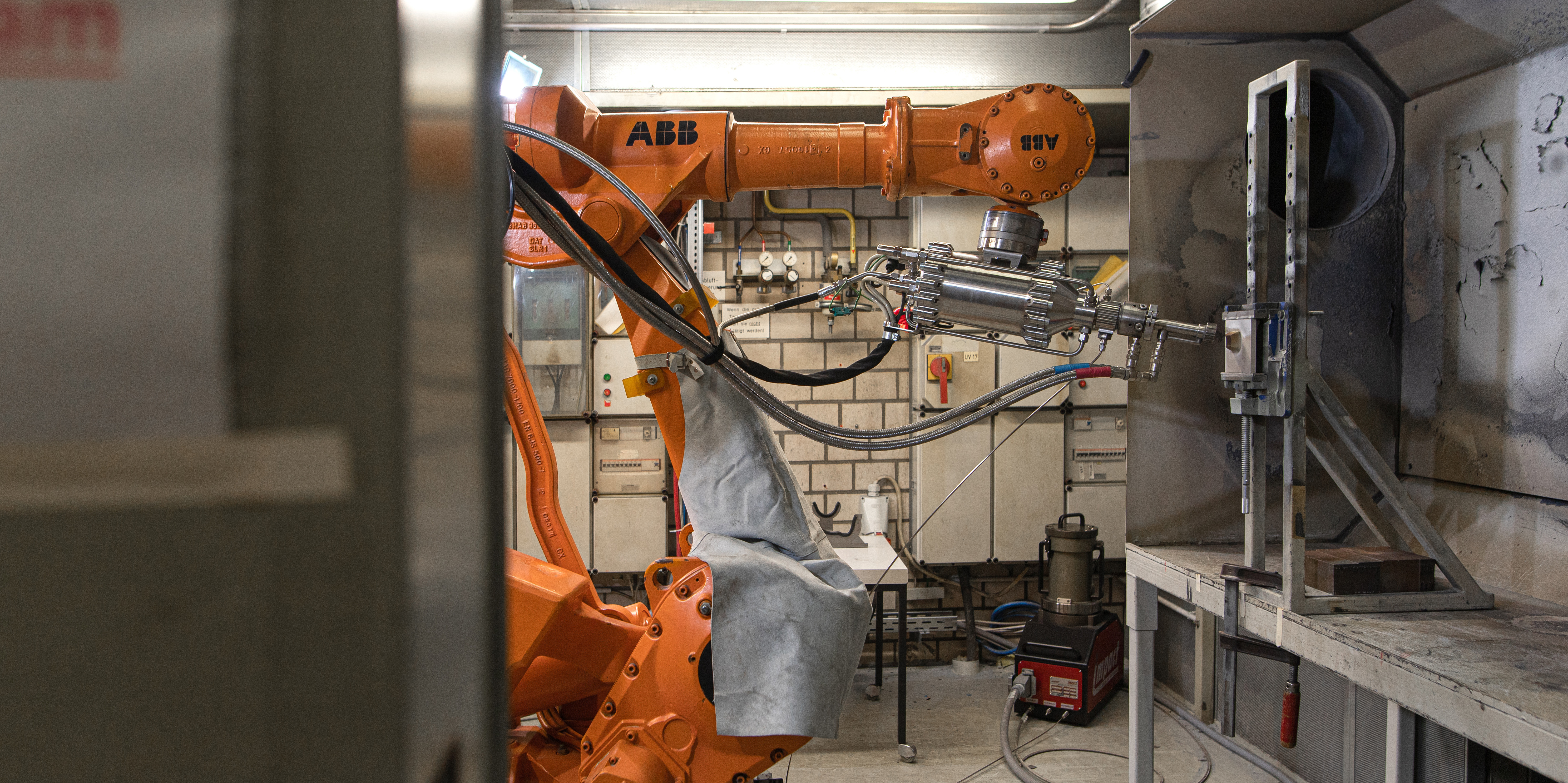

The aim of the sub-project is to further develop robot-assisted thermal spraying on the basis of efficient robot simulation. For this purpose, a generalised model is to be developed for application to different robots and also changing tools, which in particular also takes into account the dynamic effects and contributes to the optimisation of the overall process through a "fast simulation". - SFB 708 - Subproject A6

The aim of sub-project A6 is the development and management of robot-assisted, force-controlled spotting processes to optimise the geometry and surface properties of hard-coated forming tools in the production press. Sub-project A6 focuses on the development of a suitable path planning, the adaptation and integration of an empirical model for the planning of the removal process, the development of an in-process control for the regulation of the spotting process and the integration into an overall system. - SFB 876 - Subproject B3

The goal of efficient zero-defect production requires the development of resource-saving methods for real-time monitoring of production processes and prediction of quality-relevant characteristics. By learning from sensor data, real-time predictions can be made about product quality, which are used to intervene in the production process in a targeted manner and thus increase quality. While the project is focused on closing gaps in scientific research, transferability of the results to real industrial applications should not be neglected. To ensure this transfer, the developed methods need to be validated and evaluated on real data, which originate from real use cases and are associated with corresponding limitations. - SkalKomm

Specifically for order picking in conventional order picking systems in KMUs, a decision model is to be developed within the framework of this research project, which supports KMUs in systematically and specifically adapting their company-specific order picking system to short-term fluctuations in demand and market changes. - Taktarbeit - Montage

Innovative concepts and methods are needed for the targeted prevention of work-related MSDs and repetitive strain injuries, which can be used to ensure both economic and health-oriented takt work. For this purpose, the current research project explores whether the integration of specific load alternations into takt work contributes to a reduction of physical stress and thus has the potential to prevent occupational diseases. In the given context, specific load alternations mean that muscles loaded in one activity segment are specifically relieved or loaded differently in the next activity segment. Within the scope of the study, criteria for the targeted use of such specific load alternations will be developed and transferred into a methodological approach. With the help of this approach, companies should be enabled to take specific load alternations into account when redesigning or adapting takt work. - Variana

Multivariate analysis methods for strategy selection in the post-series - Development of a system for strategy selection by multivariate analysis methods in the post-series supply (NSV) of electronic assemblies - VariPro

Variability-based machine allocation planning for customer order-specific production in KMUs - VEIN

Trust and learning in the incremental, error-induced innovation process - Investigation of technical and work organisation success factors of a continuous adaptation of production processes to constantly changing customer requirements while solving the problems arising in this context. - ViReBa

As part of the KMU-Innovative: Resource and Energy Efficiency funding programme, the vibration cleaning technology is to be further developed for its use in industrial series production. The focus here is on both the development of the cleaning technology suitable for series production and its integration into lean production lines à la Toyota. - WaProTek

The aim of the WaProTek research project (process architectures conducive to change) is to enable companies to identify the acute need for change in their production systems by means of coordinated process architectures conducive to change, to identify their technical, logistical, organisational and human resources, to systematically compare them with the range of services offered by equipment suppliers and service providers, to design economic solutions and to operate them in a qualified manner.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/2/6/csm_Altes_Maschinenbau-Gebaeude_3a1a87015a.jpg)